Mobile locksmiths require specialized vehicle organization to provide efficient service delivery across various locations. The mobile workshop serves as both transportation and operational headquarters, demanding thoughtful design for maximum productivity.

Professional locksmiths rely on vehicle functionality for emergency response capabilities and routine service calls. Efficient van racking directly impacts service quality, response time, and the overall professional impression conveyed to clients.

Selecting the Right Van for Locksmith Services

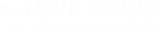

Van selection creates the foundation for an effective mobile locksmith operation. Mid-sized commercial vans like the Ford Transit, Mercedes Sprinter, or Nissan NV series provide optimal balance between maneuverability and storage capacity.

The security technician must evaluate cargo space dimensions against anticipated tool inventory and workspace requirements. Dr. Michael Reynolds of the Mobile Trade Association notes, "Vehicle selection represents the most significant initial investment for service professionals, impacting all subsequent organizational decisions."

Professional Van Racking Systems for Locksmiths

Custom racking systems provide tailored solutions addressing specific needs of security professionals. Modular systems offer flexibility for evolving business requirements and inventory adjustments.

Aluminum racking delivers superior strength-to-weight ratio compared to steel alternatives while resisting corrosion. Professional installation ensures proper anchoring to vehicle structure, preventing dangerous shifting during transport or accidents.

|

Racking Type |

Advantages |

Disadvantages |

Best For |

|

Custom Wood |

Low initial cost, DIY-friendly, fully customizable |

Heavier weight, less durable, requires maintenance |

Budget-conscious startups |

|

Modular Metal |

Reconfigurable, professional appearance, durable |

Higher cost, potential rattling, standardized sizes |

Growing businesses |

|

Aluminum Systems |

Lightweight, corrosion-resistant, professional |

Highest cost, specialized installation |

Established professionals |

Essential Locksmith Tool Organization Principles

Effective tool organization requires categorization based on frequency of use and related functions. Primary access zones should contain frequently used items like key blanks, tension wrenches, and pick sets.

Security technicians benefit from visual organization systems using color-coding or labeling for rapid identification. Research by the Locksmith Industry Association found that organized vans reduce service time by up to 34% compared to poorly organized alternatives.

The most effective tool arrangements follow these principles:

-

Position frequently used tools at waist height for ergonomic access

-

Store heavy equipment low and centered for stability

-

Group related tools together by function

-

Implement one-touch access for emergency response items

-

Secure loose items to prevent movement during transit

Secure Storage Solutions for Valuable Locksmith Equipment

Professional locksmith equipment represents substantial financial investment requiring protection from theft and damage. Secure lockable cabinets or drawers safeguard expensive diagnostic tools, key cutting machines, and specialized equipment.

Van security features should include reinforced doors, window shields, and alarm systems. Mobile security professionals must implement multi-layered protection strategies balancing accessibility with security.

Workspace Ergonomics for the Mobile Locksmith

Ergonomic workspace design prevents repetitive strain injuries and enhances productivity throughout the workday. Lock specialists benefit from proper tool positioning at appropriate heights to reduce bending, reaching, and uncomfortable postures.

Adequate lighting systems prevent eye strain during detailed work with small components and intricate mechanisms. Comfortable seating or standing options accommodate varied tasks performed within the vehicle workspace.

Creating a Mobile Key-Cutting Station

Mobile key-cutting stations require sturdy mounting solutions to prevent vibration and ensure accurate cutting. Dust collection systems protect sensitive equipment and maintain air quality within the confined workspace.

Key-cutting equipment needs reliable power supply through inverters or vehicle integration systems. The workstation should include secure blank key storage and waste collection containers for metal shavings.

Organizing Lock Inventory in Your Service Vehicle

Lock inventory organization enables quick retrieval of appropriate hardware for various service calls. Transparent containers with clear labeling facilitate visual identification of lock types, sizes, and compatible components.

Systematic arrangement prevents inventory loss and streamlines restocking procedures. Security professionals benefit from inventory tracking systems to maintain appropriate stock levels for common service needs.

Emergency Response Optimization for Locksmiths

Emergency response optimization requires strategic placement of essential tools for rapid deployment. Front-accessible emergency kits should contain pick sets, tension tools, and bypass equipment for immediate availability.

Response efficiency depends on logical workflow design from vehicle entry to tool retrieval. Dr. Sarah Chen's research in trade efficiency found that "optimized emergency response layouts can reduce service initiation time by up to 78% in critical situations."

Integrating Power Solutions in Your Locksmith Van

Power integration solutions enable operation of electronic equipment regardless of location. Inverter systems convert vehicle power to standard outlets for charging batteries and operating corded tools.

Auxiliary power systems support extended operation without depleting the primary vehicle battery. Modern power management includes USB charging ports, dedicated tool charging stations, and power backup capabilities.

|

Power Solution |

Capacity |

Best Application |

Considerations |

|

Basic Inverter |

300-500W |

Small tools, charging |

Limited run time, vehicle must be running |

|

Deep Cycle Battery |

1000-1500W |

Extended operations |

Requires maintenance, additional weight |

|

Solar Augmented |

Varies |

Environmental sustainability |

Weather dependent, higher initial cost |

Weather and Climate Considerations for Tool Storage

Climate considerations impact equipment longevity and functionality across varying work environments. Extreme temperature protection prevents damage to electronic components and battery degradation.

Humidity control systems protect metal tools from corrosion and rust development. Proper insulation maintains workable conditions inside the van during temperature extremes.

Weight Distribution and Fuel Efficiency

Strategic weight distribution ensures vehicle stability and safe handling during transport. Heavy equipment positioned low and centrally improves vehicle dynamics and reduces wear on suspension components.

Balanced loading improves fuel efficiency and reduces operational costs. The Transportation Safety Institute reports that "properly distributed cargo can improve fuel economy by up to 12% while significantly enhancing safety margins."

Professional Branding for Your Locksmith Van

Vehicle branding transforms service vans into mobile marketing platforms generating continuous visibility. Professional graphics communicate reliability and expertise to potential clients encountering the vehicle.

Clear contact information facilitates immediate service requests from prospects. A study by the Small Business Marketing Association found vehicle graphics generate between 30,000-70,000 impressions daily in urban environments.

Budget-Friendly Van Racking Ideas for New Locksmiths

New locksmith businesses can implement cost-effective storage solutions while building revenue. DIY wooden shelving provides customizable organization with minimal investment for startups.

Modular plastic storage bins offer flexibility without permanent installation requirements. Emerging security professionals should prioritize basic organization while planning for future upgrades.

Economical organization strategies include:

-

Repurposed kitchen cabinetry with reinforced mounting

-

Adjustable shelving systems from home improvement stores

-

Removable tool boxes that transition between vehicle and job site

-

Pegboard systems for vertical wall organization

-

Magnetic tool strips for metal surfaces

-

Fabric pouches for door and vertical storage

Advanced Van Customization for Established Locksmith Businesses

Established locksmith operations benefit from comprehensive vehicle customization addressing specific business needs. Integrated workbenches with vice mounts enable complex repairs within the mobile environment.

Specialized compartments for diagnostic equipment protect valuable technology investments. Dr. Thomas Williams of Professional Vehicle Organization states, "Advanced customization represents the operational difference between reactive service providers and proactive security consultants."

Maintenance and Cleaning of Your Van Racking System

Regular maintenance prevents premature deterioration of racking components and storage systems. Scheduled inspections should evaluate mounting security, drawer functionality, and structural integrity.

Cleaning protocols maintain professional appearance and prevent cross-contamination between job sites. Well-maintained systems project professionalism while extending equipment lifespan.

Conclusion: Transforming Your Service Vehicle into a Professional Mobile Locksmith Workshop

Effective van racking transforms ordinary vehicles into professional mobile workshops supporting locksmith operations. Strategic organization directly impacts service quality, efficiency, and business profitability.

Professional mobile locksmiths benefit from continuous improvement of their vehicle systems and organization. The optimized service vehicle serves as both functional workspace and business ambassador, reflecting the locksmith's commitment to professional excellence.

Frequently Asked Questions

What is the most important factor when designing a locksmith van layout? Workflow efficiency based on frequency of tool use determines optimal layout for locksmith operations.

How much should a new locksmith invest in van racking systems? New professionals should allocate 8-15% of their startup budget for basic organization while planning for modular expansion.

Can I install locksmith van racking systems myself? Basic systems can be self-installed, while professional systems with integrated features benefit from specialist installation ensuring safety and warranty coverage.

What tools should be most accessible in a locksmith van? Diagnostic equipment, pick sets, tension tools, and emergency bypass equipment require immediate accessibility.

How does van racking impact fuel efficiency? Properly distributed and secured equipment improves aerodynamics and reduces weight shifting, improving fuel economy by up to 12%.

What security features should locksmith vans include? Multiple security layers including reinforced locks, alarm systems, hidden compartments, and GPS tracking protect valuable equipment.

How often should van racking systems be evaluated and updated? Quarterly assessments identify improvement opportunities while major reorganization typically occurs every 2-3 years.

What's the best way to organize key blanks in a mobile workshop? Transparent divided containers with clear labeling organized by manufacturer and keyway provide optimal blank management.

How can I power a key cutting machine in my van? Pure sine wave inverters rated at least 20% above maximum equipment draw provide reliable power for key cutting operations.

What's the biggest mistake locksmiths make when organizing their vans? Inadequate planning for growth forces frequent disruptive reorganization instead of modular expansion.

How can I reduce noise from tools moving while driving? Rubber matting, tool shadows, and secure fastening systems prevent movement and associated noise during transit.

What's the ideal height for a mobile workbench in a locksmith van? Ergonomic workbench height positions work surface 2-4 inches below elbow height when standing to reduce strain.

How do professional locksmiths protect electronic equipment from temperature extremes? Insulated containers, climate control systems, and overnight equipment removal protect sensitive electronics from damage.

What lighting systems work best for locksmith vans? LED lighting systems with color temperatures between 4000-5000K provide accurate color rendering without excessive battery drain.

Is it better to have drawers or shelves for locksmith tools? Drawers prevent items from falling during transit but cost more, while shelves maximize visibility and accessibility with proper retention systems.