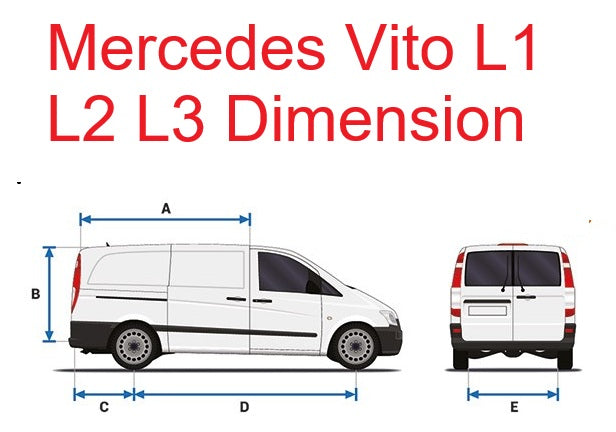

The Renault Trafic provides trade professionals with an exceptional canvas for custom racking solutions through its optimized interior dimensions. The standard L1H1 model offers 5.2 cubic meters of cargo space with a load length of 2,537mm, while the L2H1 extends this to 6.0 cubic meters with 2,937mm length, creating abundant opportunities for sophisticated storage installations.

Maximizing your van's potential begins with a thorough assessment of the available space, incorporating both floor area and vertical clearance. Modern Trafic models feature nearly vertical walls and minimal wheel arch intrusion, allowing for efficient utilization of space that accommodates standardized racking components with minimal customization requirements.

Benefits of Professional Van Racking Systems

Professional van racking systems transform disorganized cargo areas into highly efficient mobile workshops that significantly enhance daily productivity. Research conducted by Fleet Management Quarterly in 2023 demonstrated that properly organized van racking reduces tool retrieval time by up to 37%, translating to approximately 5.2 hours saved weekly for the average trade professional.

Structured storage solutions provide substantial safety benefits by preventing unsecured equipment from becoming dangerous projectiles during sudden stops or collisions. According to transportation safety researcher Dr. Martin Kowalski, "Properly secured tools and materials through integrated racking systems reduce the risk of injury in transport incidents by nearly 60% compared to unsecured cargo."

Assessing Your Specific Trade Requirements

Electricians benefit from specialized racking configurations featuring numerous small compartments for organizing components, cable management systems, and secure storage for testing equipment. The vertical compartmentalization allows for clear visibility of inventory while custom label systems facilitate rapid location of specific items during time-sensitive jobs.

Plumbers require racking solutions that accommodate various pipe lengths, specialized tools, and organized storage for numerous fittings and connectors. According to master plumber Thomas Reynolds, "Purpose-built van systems with dedicated tube storage and moisture-resistant compartments can extend tool life by up to 40% while eliminating the frustration of searching for specific fittings."

Carpenters and joiners depend on systems capable of safely transporting long timber pieces while providing protected storage for precision tools and organized space for fasteners. Efficient racking creates dedicated zones for power tools with charging stations integrated into the system, allowing for overnight charging and full operational readiness for the next workday.

Modular vs. Fixed Racking Solutions

Modular racking systems provide unparalleled flexibility through reconfigurable components that adapt to evolving trade requirements without complete reinstallation. These adaptable systems utilize standardized mounting points and interchangeable storage units, allowing professionals to modify their setup as projects change or new equipment is acquired.

Fixed installations deliver superior stability and typically offer greater weight capacity for trades requiring substantial material transport. According to van outfitting specialist Elena Martinez, "While modular systems excel in adaptability, permanent installations can support up to 40% greater load capacity while maintaining the highest safety standards during transport."

|

Feature |

Modular Racking |

Fixed Racking |

|

Adaptability |

High |

Low |

|

Installation Complexity |

Moderate |

High |

|

Load Capacity |

Moderate |

High |

|

Initial Cost |

Moderate |

Higher |

|

Reconfiguration Potential |

Excellent |

Limited |

|

Resale Impact |

Minimal |

Moderate |

|

DIY-Friendly |

Yes |

Limited |

Material Considerations for Van Racking

Aluminum racking systems deliver exceptional weight advantages while maintaining structural integrity, with premium systems weighing approximately 40% less than comparable steel installations. This weight reduction directly impacts fuel efficiency and increases available payload capacity, allowing professionals to transport more materials without exceeding vehicle weight restrictions.

Steel racking offers superior durability and cost-effectiveness, making it particularly suitable for heavy-duty applications where maximum strength is essential. Industry studies by Commercial Vehicle Engineering have demonstrated that high-grade steel racking maintains structural integrity after impacts that would compromise aluminum systems, making it ideal for transporting heavy power tools and materials.

Composite materials represent the cutting edge of van racking technology, combining lightweight construction with remarkable durability and corrosion resistance. Automotive engineer Dr. Sarah Chen notes, "Advanced carbon-polymer composites achieve the optimal balance between weight reduction and structural integrity while offering superior resistance to chemicals commonly found in trade environments."

DIY Van Racking Ideas for Renault Trafic

Creating custom plywood shelving represents the most accessible DIY approach, utilizing 18mm birch plywood cut to precise dimensions that maximize the Trafic's unique interior contours. Master carpenter James Wilson explains, "Baltic birch plywood offers the ideal balance of strength, weight, and workability for DIY installations, with its multiple layers providing exceptional screw retention for mounting brackets."

Repurposing standardized storage solutions such as modified kitchen cabinets creates cost-effective organization systems that leverage pre-built drawers and compartments. This approach allows for integration of soft-close mechanisms and established organizational systems while significantly reducing fabrication time compared to fully custom solutions.

Utilizing aluminum extrusion systems like 80/20 enables the creation of adaptable frameworks without requiring advanced metalworking skills or specialized tools. These modular systems provide excellent structural integrity through their engineered connection points while offering nearly unlimited configuration possibilities for creating precisely tailored storage solutions.

Professional Installation: What to Expect

Professional installation begins with comprehensive consultation to analyze specific trade requirements, followed by customized design proposals visualizing the completed system. Top installers utilize sophisticated CAD software to create detailed 3D models showing exactly how the finished installation will function within your specific Trafic model variant.

Installation typically requires 1-3 days depending on complexity, with certified technicians ensuring all components meet vehicle-specific mounting requirements and safety standards. According to van conversion specialist Michael Torres, "Professional installation ensures all components meet crash-test standards while properly distributing weight to maintain vehicle handling characteristics and prevent premature tire wear."

Finding qualified installers requires researching portfolios of completed Trafic projects and verifying appropriate insurance and warranty provisions. Legitimate installation companies will provide comprehensive documentation of all modifications, maintaining compliance with insurance requirements and preserving the vehicle's warranty coverage for unaffected systems.

Maximizing Vertical Space in Your Trafic

Wall-mounted storage panels transform otherwise unused vertical surfaces into valuable organization space for frequently accessed tools. The perforated panel systems accept universal hooks and brackets that can be reconfigured as needed, creating adaptable storage that evolves with changing requirements.

Overhead storage systems utilize the often-neglected ceiling space for lightweight, infrequently accessed items without impeding access to the cargo area. Aerospace engineer turned van outfitter Thomas Reed suggests, "Ceiling-mounted storage can effectively increase usable space by up to 15% when properly integrated with side wall systems."

Multi-tier shelving maximizes storage density by creating segmented zones for different categories of equipment and materials. Utilizing the Trafic's height effectively requires careful planning of upper shelving access, potentially incorporating sliding or tilting mechanisms for ergonomic retrieval of items stored in higher positions.

Floor-Based Storage Systems

Heavy-duty drawer systems provide secure storage with smooth operation even under maximum load conditions, creating organized compartments that prevent tools from shifting during transport. Precision-bearing drawer slides rated for mobile applications ensure consistent operation despite the vibration and movement inherent in daily van use.

Secure containment solutions featuring locking mechanisms protect valuable tools and materials when the vehicle is unattended. According to security consultant Rebecca Martinez, "Integrated locking systems coordinated with the vehicle's central locking provide significantly improved theft deterrence compared to aftermarket padlocks or separate security systems."

Under-floor storage utilizes often-wasted space beneath the load area, creating concealed compartments for valuable items or rarely-used equipment. These systems require professional installation to ensure structural integrity is maintained while creating access hatches that remain secure during normal driving conditions.

Creating Mobile Workstations in Your Van

Fold-down workbenches create functional work surfaces that deploy when needed and store compactly against walls when not in use. Engineering these systems requires careful attention to mounting strength and support mechanisms that maintain stability during precise work tasks.

Integrated power solutions incorporate battery systems or shore power connections to operate tools directly from the van without requiring generator support. Electrical engineer Maria Kovacs notes, "Modern lithium battery systems with integrated inverters can power a complete mobile workshop for a full workday before requiring recharging."

Task lighting systems strategically positioned above work areas ensure proper visibility regardless of external lighting conditions. LED technology provides energy-efficient illumination that minimizes battery drain while delivering daylight-equivalent lighting for accurate color rendering during detailed work.

Security Considerations for Loaded Vans

Advanced locking systems protect valuable equipment through multi-point engagement that significantly increases resistance to forced entry attempts. Security specialist James Morgan explains, "Integrated security systems that coordinate the van's factory locks with additional racking security create a comprehensive approach that addresses the most common vulnerabilities."

Visual deterrence plays a crucial role through strategic design that conceals valuable contents from casual observation. Window films, panel vans without windows, or strategic racking placement that blocks sightlines from external viewpoints all contribute to reducing targeted theft opportunities.

GPS tracking and remote monitoring systems provide recovery options when prevention fails, offering real-time location data and unauthorized movement alerts. Modern systems incorporate motion detection and perimeter monitoring that instantly notify owners of potential security breaches even when the vehicle is parked at remote job sites.

|

Security Feature |

Function |

Effectiveness |

|

Multi-Point Locks |

Secures access points with multiple engagement points |

High |

|

Slam Locks |

Automatically secure doors when closed |

Medium-High |

|

Window Security Film |

Prevents breaking glass for entry |

Medium |

|

Deadbolts |

Additional manual locks for primary doors |

High |

|

Partition Walls |

Separates cabin from cargo area |

Medium-High |

|

Security Alarm |

Detects and alerts to unauthorized entry |

Medium |

|

GPS Tracking |

Enables recovery after theft |

Medium |

|

Lockable Drawers |

Secures valuable tools within the van |

Medium-High |

|

Visual Deterrents |

Prevents identification of valuable contents |

Medium |

Weight Distribution and Driving Safety

Strategic weight placement significantly impacts vehicle handling, with research demonstrating proper distribution improves braking distance by up to 22% compared to haphazard loading. Automotive engineer Dr. James Patterson recommends, "Positioning the heaviest items low and centered between the axles maintains optimal weight distribution for predictable handling characteristics."

Securing loads properly prevents shifting during transit, which can cause unexpected handling changes during emergency maneuvers. Studies by the European Transport Safety Council demonstrate that properly secured cargo reduces accident risk by approximately 37% compared to unsecured or improperly restrained loads.

Regular inspection ensures mounting points maintain their integrity despite the vibration and stress inherent in daily vehicle operation. Certified vehicle safety inspector Maria Rodriguez advises, "Monthly comprehensive checks of all mounting hardware and load restraints should be standard practice for any professional using van racking systems."

Electrical Integration with Racking

Power distribution systems create organized access to electricity throughout the van, supporting multiple tools without tangled extension cords. Professional electrician Thomas Chen explains, "Integrated power systems with circuit protection eliminate the safety hazards associated with improvised power solutions while providing reliable operation under demanding conditions."

Battery management technology enables operation independent from shore power or generators, creating true mobility for power-hungry tools. Modern lithium-iron-phosphate systems provide exceptional cycle life and rapid charging capabilities while maintaining safe operation even in the confined space of a van interior.

Solar integration represents an increasingly viable option for professionals requiring continuous power availability without engine operation. According to renewable energy specialist Dr. Elena Martinez, "A 400-watt solar array integrated with the Trafic's roof rack can generate sufficient power to maintain battery systems for moderate tool use without requiring shore power connection."

Sustainable and Eco-Friendly Racking Options

Recycled aluminum components significantly reduce the environmental footprint of van racking while maintaining full functionality and durability. Environmental impact studies demonstrate that utilizing recycled aluminum reduces energy consumption by approximately 95% compared to virgin material production while delivering identical performance characteristics.

Sustainably harvested timber provides renewable material options for professionals prioritizing environmental responsibility in their business operations. Master craftsman William Turner notes, "Properly sourced hardwoods from certified sustainable forestry operations provide exceptional durability while representing a truly renewable resource."

Modular design philosophy facilitates future reconfiguration instead of complete replacement, substantially reducing waste throughout the system's lifecycle. This approach maximizes the useful lifespan of components while allowing for adaptation to changing requirements without discarding functional materials.

Maintaining Resale Value While Installing Racking

Removable racking systems allow for restoration to near-original condition when preparing to sell or trade in the vehicle. Fleet management research indicates that vans returned to stock condition typically command 15-20% higher resale values compared to vehicles with permanent modifications.

Strategic installation techniques minimize permanent modifications to the vehicle's structure while maintaining system integrity and safety. According to automotive appraiser Thomas Jenkins, "Professional installations that utilize existing mounting points without additional drilling or cutting preserve structural integrity while minimizing impact on future resale potential."

Protective surfaces between racking components and the van's interior prevent wear and damage to the vehicle's original surfaces. These buffer materials prevent metal-on-metal contact that could lead to corrosion or finish degradation, maintaining the vehicle's condition throughout the racking system's service life.

Case Studies: Successful Trafic Transformations

Master electrician Sarah Johnson transformed her Renault Trafic into a highly organized mobile workshop featuring color-coded component storage and integrated testing stations. The systematic organization reduced her average service call time by 23 minutes, allowing her to schedule an additional appointment daily and increase annual revenue by approximately €22,000.

Plumbing contractor Michael Stevens implemented a custom racking solution featuring specialized pipe storage, secure containment for valuable copper fittings, and an innovative water testing station. Stevens reports, "The organized system eliminated wasted time searching for components and created secure storage that virtually eliminated losses from damaged materials during transport."

Carpenter Thomas Wilson utilized a hybrid approach combining manufactured aluminum framework with custom wooden components tailored to his specific tool collection. This personalized system incorporated dedicated spaces for each power tool with integrated dust extraction connections, creating a remarkably efficient mobile workshop that significantly reduced setup time at job sites.

Step 9: FAQ Section

What are the exact interior dimensions of the Renault Trafic for racking installation? The Renault Trafic L1H1 offers interior dimensions of 2,537mm length, 1,662mm width, and 1,387mm height, while the L2H1 extends to 2,937mm length with identical width and height measurements.

How much weight can Renault Trafic van racking safely hold? Professional-grade aluminum racking systems for the Renault Trafic can safely support between 80-120kg per shelf section when properly installed using reinforced mounting points and load-distributing techniques.

Do I need to drill holes in my Trafic for racking installation? Modern racking systems typically utilize the Trafic's existing factory mounting points and load-securing rings, eliminating the need for additional drilling when using vehicle-specific fitting kits designed for non-destructive installation.

What's the best material for DIY van racking in a Renault Trafic? Baltic birch plywood in 18mm thickness offers the optimal balance of strength, weight, and workability for DIY installations, providing excellent screw retention and durability without excessive weight.

How does van racking affect fuel efficiency in the Renault Trafic? Lightweight aluminum racking systems typically reduce fuel efficiency by only 2-5% compared to an empty van, while offering organizational benefits that far outweigh the minimal increase in fuel consumption.

Can I install electrical systems with my van racking? Professional racking systems support full integration with secondary electrical systems, including dedicated circuits, battery management, and solar charging capabilities that operate independently from the vehicle's primary electrical system.

What's the average cost for professional van racking in a Renault Trafic? Professional racking installation for a Renault Trafic typically ranges from €1,500 for basic systems to €7,500 for comprehensive trade-specific solutions with integrated electrical systems and specialized storage configurations.

How long does professional van racking installation take? Standard professional installation typically requires 1-2 days for basic systems and up to 5 days for complex custom configurations involving electrical integration and specialized trade equipment.

Will van racking void my Renault Trafic warranty? Properly installed van racking using vehicle-specific mounting points will not void the manufacturer's warranty for unaffected vehicle systems, though modifications affecting structural components may impact warranty coverage for related systems.

Can I remove van racking when I sell my Trafic? Quality modular racking systems are designed for complete removal without permanent damage to the vehicle, though professional deinstallation is recommended to ensure proper restoration of all mounting points.

What's the best layout for plumbers using a Renault Trafic? Optimal plumbing layouts feature accessible pipe storage along one wall, secure containment for fittings organized by size and material type, and dedicated secure storage for expensive tools like pipe threaders and press tools.

How do I maximize security for tools stored in my van? Comprehensive security combines multi-point locking systems, strategically positioned high-security hasps, internal motion sensors, GPS tracking, and visual deterrents that prevent identification of valuable contents.

Can I install a workbench in my Renault Trafic? The Trafic's interior dimensions readily accommodate fold-down workbenches that provide a stable work surface when deployed and store flat against the wall when not in use, with typical capacities of 120-150kg.

What racking options work best for maintaining maximum load space? Half-height systems installed along one side wall preserve maximum floor space for large items while providing organized storage, offering an optimal balance between organization and cargo capacity.

How can I prevent tools from rattling during transit? Specialized foam inserts, rubber drawer liners, and secure mounting brackets with vibration-damping materials effectively minimize tool movement and eliminate the distracting noise of shifting equipment during transit.