Key Takeaways

-

Purpose-built van racking systems can save painters up to 1 hour per day in tool and material retrieval

-

Vertical paint storage solutions prevent spillage while maximizing accessible storage space

-

Dedicated sections for wet and dry materials prevent cross-contamination and material damage

-

Strategic tool organization based on frequency of use improves workflow efficiency

-

Proper weight distribution and secure storage prevents damage to both equipment and vehicle

-

Customizable modular systems allow adaptation as business needs evolve

Browse our professional painter van organization solutions

Introduction: Why Proper Organization Matters for Professional Painters

For professional painters, a well-organized van isn't just about neatness—it's a critical business asset that directly impacts productivity, professionalism, and profitability. The average painter spends 30-45 minutes daily searching for tools and materials in a disorganized van, translating to over 180 hours of lost productivity annually. Beyond time savings, proper organization prevents paint spillage, reduces material waste, extends tool lifespan, and creates a professional impression with clients.

Your van serves as a mobile workshop, inventory storage, and professional showcase. The challenge lies in creating an organization system that accommodates the unique needs of the painting profession: safely transporting liquid paints, organizing tools of varying sizes, storing small hardware, managing long items like extension poles, and keeping wet and dry materials separated.

This comprehensive guide explores purpose-designed van racking solutions specifically for professional painters. Whether you're a solo operator with a compact van or manage a fleet of painting vehicles, these ideas will help transform your van into an efficient, organized workspace that enhances your daily operations and professional image.

Understanding a Painter's Specific Storage Needs

Essential Items Requiring Organization

Professional painters carry a diverse inventory that presents unique storage challenges:

-

Liquid paints and finishes: Must be stored upright to prevent spillage

-

Various sized brushes and rollers: Require protective storage to maintain quality

-

Extension poles and ladders: Long items that need secure fastening

-

Power tools: Sanders, sprayers, and heat guns that benefit from dedicated spaces

-

Drop cloths and protective materials: Bulky items that need compression

-

Sundries and small hardware: Items that easily disappear without proper organization

-

Safety equipment: Masks, goggles, and protective gear requiring clean storage

Unlike other trades that primarily carry solid tools and materials, painters must consider both wet and dry storage needs alongside significant variations in item sizes.

Space Utilization Challenges in Painter's Vans

The typical painter's van presents several spatial challenges:

-

Vertical storage limitations: Standard shelving often wastes valuable vertical space

-

Paint can security: Preventing tipping during transport

-

Clean/dirty separation: Keeping dust-generating tools away from finishing materials

-

Weight distribution: Managing the substantial weight of paint supplies

-

Accessibility priority: Ensuring frequently used items remain easily reachable

-

Seasonal equipment variation: Accommodating different tools for interior versus exterior seasons

A well-designed painter's organization system addresses these challenges through purpose-built solutions rather than generic storage options.

Foundation Elements of Painter-Specific Van Racking

Paint and Finish Storage Solutions

Safe paint transport forms the foundation of any painter's organization system:

Vertical Paint Can Storage

-

Adjustable dividers: Create customizable slots for different can sizes

-

Anti-slip surfaces: Prevent can movement during transport

-

Locking mechanisms: Additional security for valuable or hazardous materials

-

Containment lips: Capture potential spills before they spread

-

Tiered designs: Allow visibility of all cans without unstacking

Industry studies show that proper vertical storage reduces paint damage by over 90% compared to horizontal or stacked transport methods.

Specialty Coating Compartments

-

Temperature-controlled sections: Protect temperature-sensitive products

-

Hazardous material containment: Separate storage for solvents and flammables

-

Quick-access bays: Designated areas for most frequently used finishes

-

Sealed compartments: Prevent cross-contamination between products

-

Clear labeling systems: Identify contents without opening containers

Professional systems often incorporate color-coding or labeling tracks to further streamline identification.

Tool Organization Frameworks

Effective tool organization balances protection with accessibility:

Brush and Roller Systems

-

Ventilated brush holders: Allow proper drying between uses

-

Suspended roller storage: Prevents nap compression and damage

-

Length-graduated slots: Accommodate various brush sizes

-

Protective covers: Shield delicate bristles during transport

-

Removable caddies: Allow tools to be carried to worksite as a set

Many professional painters report that proper brush storage extends tool life by 30-50%.

Power Tool Security

-

Foam-lined drawers: Custom-cut foam inserts for specific tools

-

Charging stations: Integrated power solutions for cordless tools

-

Lockable compartments: Secure expensive equipment

-

Vibration-dampening mounts: Protect sensitive equipment during transit

-

Quick-release brackets: Allow rapid deployment at job sites

The most effective systems balance security with accessibility, recognizing that over-securing creates usage barriers.

Ladder and Extension Equipment Management

Long items require specialized mounting solutions:

Interior Ladder Storage

-

Ceiling-mounted racks: Utilize overhead space for stepladders

-

Side-wall brackets: Secure ladders against interior walls

-

Quick-release clamps: Allow one-handed retrieval and storage

-

Multi-position mounts: Accommodate different ladder types

-

Fold-down supports: Maximize space when ladders are removed

Proper interior mounting can reduce ladder damage by up to 80% compared to unsecured transport.

Exterior Rack Systems

-

Aerodynamic designs: Reduce fuel consumption and noise

-

Side-mounted options: Keep roof clear for other equipment

-

Multi-tier systems: Carry extension ladders and stepladders together

-

Assisted loading mechanisms: Reduce strain during ladder mounting

-

Integrated locking systems: Prevent theft during site visits

The latest exterior systems incorporate lightweight materials that add minimal weight while maximizing security.

Specialized Organization Solutions for Painters

Small Parts and Hardware Management

The multitude of small items painters use requires dedicated organization:

Fastener and Hardware Systems

-

Transparent containers: Allow visual identification without opening

-

Graduated compartments: Separate different sizes and types

-

Removable bins: Take only needed items to work areas

-

Labeling systems: Quickly identify contents

-

Inventory tracking: Visual indicators of low stock levels

Professional painters report spending 15-20% less on replacement hardware after implementing proper small parts organization.

Sandpaper and Abrasives Organization

-

Grit-specific dividers: Separate different abrasive grades

-

Flat storage options: Prevent warping and damage

-

Quick-reference systems: Easily identify grit levels

-

Dust-free compartments: Protect from contamination

-

Usage tracking: Monitor consumption patterns

Properly organized abrasives last 25-30% longer due to reduced damage during storage and retrieval.

Wet Area and Cleanup Station

Effective cleanup facilities improve both efficiency and professionalism:

Integrated Water Systems

-

Fresh water containers: Provide cleaning capability on-site

-

Gray water collection: Environmentally responsible waste handling

-

Hand washing stations: Improve site cleanliness

-

Tool cleaning areas: Designated spaces for brush washing

-

Sealed compartments: Contain water and prevent leakage

Mobile cleanup stations save an average of 15-20 minutes per job in transport time to cleaning locations.

Waste Management Solutions

-

Separated waste containment: Different receptacles for various waste types

-

Compactible bag storage: Maximize space efficiency

-

Hazardous material handling: Proper containment for solvent-soaked rags

-

Recycling systems: Separate recyclable materials

-

Exterior access options: Remove waste without entering the van

Proper waste management systems reduce cross-contamination issues by over 75%.

Mixing and Preparation Areas

Dedicated workspace improves on-site efficiency:

Mobile Workstations

-

Fold-down surfaces: Create workspace when needed

-

Integrated lighting: Ensure proper color visibility

-

Stain-resistant materials: Facilitate easy cleaning

-

Height-adjustable platforms: Improve ergonomics

-

Secure mounting points: Hold mixing containers steady

Mobile preparation areas save an average of 30 minutes per job in setup and breakdown time.

Tinting and Colorant Storage

-

Vertical storage racks: Keep tints organized and visible

-

Spill containment systems: Prevent cross-contamination

-

Temperature-controlled areas: Protect sensitive colorants

-

Secure fastening: Prevent movement during transport

-

Quick-access positioning: Place near mixing stations

Purpose-designed tint storage reduces color matching errors by up to 40%.

Modular and Adaptable Systems for Different Van Types

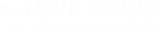

Small Van Solutions (Compact/Connect Vans)

Maximizing limited space in smaller vehicles:

-

Wall-to-ceiling utilization: Make use of every available surface

-

Multi-function components: Storage that serves multiple purposes

-

External accessories: Roof racks and rear door options to expand capacity

-

Slide-out systems: Access storage without entering the vehicle

-

Prioritized storage: Focus on most essential items

Even in compact vans, proper organization can accommodate equipment for 90% of typical painting jobs.

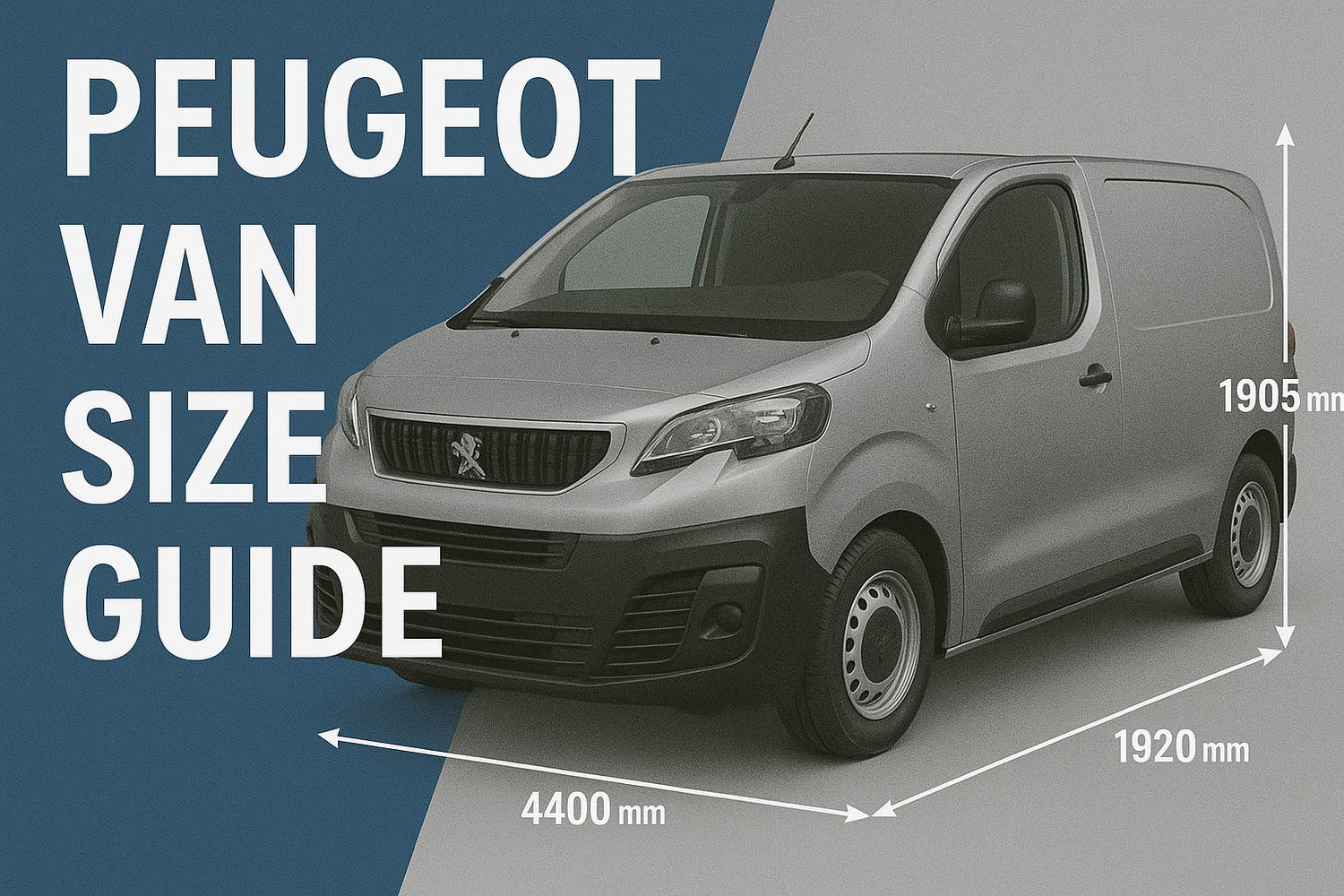

Medium Van Configurations (Transit/Sprinter)

Balancing capacity with organization in mid-sized vans:

-

Zoned storage areas: Dedicated sections for different types of materials

-

Central aisle optimization: Maintain accessibility while maximizing storage

-

Height-tiered organization: Most frequent items at waist level

-

Multi-level systems: Utilize full height with appropriate accessibility

-

Wheel well integration: Turn obstacle areas into functional storage

Medium vans with proper organization can typically reduce return trips to supply stores by 60-70%.

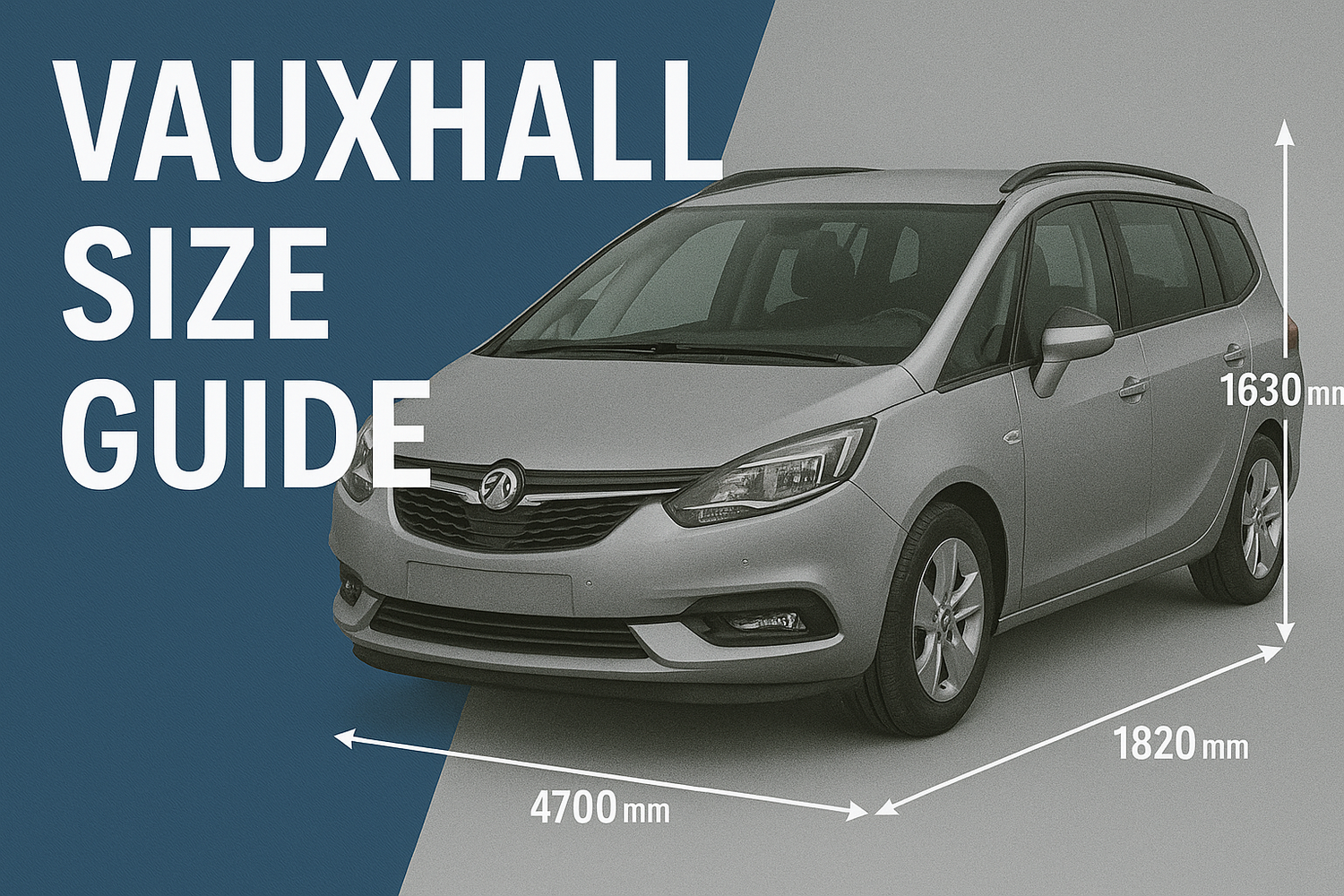

Large Van and Mobile Workshop Setups

Creating comprehensive systems for larger vehicles:

-

Dedicated workspace areas: Interior sections for on-site preparation

-

Inventory management systems: Track and manage larger material stocks

-

Specialized equipment zones: Separate areas for spray equipment or specialty tools

-

Climate-controlled sections: Protect temperature-sensitive materials

-

Multiple access points: Allow retrieval without complete entry

The most sophisticated large van systems effectively function as mobile paint stores and workshops combined.

Implementation Strategies and Considerations

Budget-Friendly Starter Systems

Building effective organization on a limited budget:

-

Phased implementation: Start with essential systems and expand

-

DIY-professional hybrid approach: Combine manufactured and custom elements

-

Prioritized investment: Focus first on paint storage and core tool organization

-

Adaptable foundations: Begin with systems that can be expanded later

-

Multi-purpose solutions: Select equipment serving multiple organizational needs

Many professional painters begin with core systems costing £500-1,000 and expand as their business grows.

Professional Installation vs. DIY Approaches

Considerations for installation methods:

-

Professional advantages: Precision fitting, warranty protection, and rapid installation

-

DIY benefits: Cost savings, customization control, and gradual implementation

-

Hybrid options: Professional foundations with DIY customization

-

Installation time factors: Professional installation typically completed in 1-2 days versus 1-2 weeks of evenings/weekends for DIY

-

Long-term considerations: Resale value improvement with professional systems

The installation approach should align with your technical skills, available time, and budget considerations.

Future-Proofing Your Organization System

Building adaptability for business evolution:

-

Modular foundations: Core systems that allow component changes

-

Expansion capacity: Initial installations with room for growth

-

Technology integration preparation: Power and mounting options for future technology

-

Business evolution anticipation: Flexibility for changing service offerings

-

Vehicle transition planning: Systems that can transfer to new vehicles

Forward-thinking organization systems retain approximately 60-70% of their value when transferred to new vehicles.

Safety and Efficiency Considerations

Weight Distribution and Secure Storage

Ensuring safe vehicle operation:

-

Balance planning: Distribute weight evenly side-to-side and front-to-back

-

Payload awareness: Stay within vehicle manufacturer specifications

-

Heavy item placement: Position weighty items low and over/between axles

-

Securing mechanisms: Prevent movement during transport or sudden stops

-

Regular weight assessment: Periodically check distribution as inventory changes

Proper weight distribution can improve fuel efficiency by 8-12% while reducing tire and brake wear.

Hazardous Material Handling and Storage

Managing painting-specific safety concerns:

-

Ventilation considerations: Proper airflow for solvent and chemical storage

-

Temperature management: Prevent exposure to extreme temperatures

-

Spill containment systems: Capture and control potential leaks

-

Clear labeling: Identify hazardous materials for proper handling

-

Separation principles: Keep incompatible materials apart

Purpose-designed hazardous material storage significantly reduces workplace incidents and exposure risks.

Ergonomics and Accessibility Planning

Preventing injury and improving efficiency:

-

Frequency-based positioning: Most used items at easy reach heights

-

Weight considerations: Heavier items positioned to minimize lifting strain

-

Entry/exit optimization: Clear pathways and stable stepping surfaces

-

Reaching reduction: Minimize overhead reaching for regular items

-

Loading/unloading efficiency: Systems that facilitate easy transfer to worksites

Ergonomically designed systems typically reduce work-related strain injuries by 30-40% among painting professionals.

FAQs: Painter's Van Organization Systems

What's the most important area to organize first in a painter's van?

The priority area for initial organization should be your paint and finish storage. This focus delivers several immediate benefits:

-

Safety improvement: Prevents dangerous spills and hazardous material incidents

-

Cost savings: Reduces product waste from damaged containers

-

Time efficiency: Improves access to your primary materials

-

Quality preservation: Maintains product integrity through proper storage

Most professional painters implement a vertical paint storage system with adjustable dividers as their first organization upgrade. These systems typically cost between £150-350 depending on capacity and feature set, but deliver immediate returns through reduced wastage and improved efficiency.

For budget-conscious approaches, start with a basic paint can securing system and expand to more comprehensive solutions as finances allow. Even simple DIY dividers combined with anti-slip matting can significantly improve over unsecured transport.

How do I manage wet tools and materials in my van?

Managing wet tools requires a multi-faceted approach:

-

Dedicated "wet zone": Create a specific area with water-resistant surfaces

-

Ventilated storage: Provide airflow around damp items to prevent mildew

-

Isolation systems: Keep wet items separated from materials that could be damaged

-

Drainage consideration: Implement containment for excess moisture

-

Quick-dry features: Include elements that accelerate drying between jobs

The most effective wet material management systems combine sealed containers for items like freshly-washed brushes with ventilated storage that promotes drying. Consider removable brush holders that can be taken into job sites and returned to ventilated docking stations in the van.

For larger operations, some professional painters implement ultrasonic cleaning stations with proper waste water containment, which can extend brush life by up to 300% while ensuring proper environmental compliance.

What's the most cost-effective way to organize a painter's van?

For painters on a budget, focus on these high-value improvements:

-

DIY paint dividers: Create adjustable dividers using plywood and foam padding

-

Tool boards: Install pegboard or slotted panels for customizable tool storage

-

Bucket organization systems: Use stacking bucket systems with dividers for sundries

-

Tension poles: Install adjustable poles to secure ladders and long items

-

Milk crate modularity: Implement standardized crates with custom dividers

Many successful painters start with a hybrid approach, investing in professional-grade paint storage (£150-250) while implementing DIY solutions for tools and sundries. This balanced approach addresses the most critical safety concerns while managing costs.

The most important principle is standardization—whatever system you choose, maintain consistency so items have dedicated locations. Even simple systems work effectively when consistently implemented.

How do I organize my van differently for interior versus exterior painting jobs?

Seasonal flexibility requires thoughtful organization:

-

Modular tool kits: Create dedicated interior and exterior tool collections

-

Seasonal rotation areas: Designate spaces that change function seasonally

-

Core/specialty separation: Maintain everyday items centrally while rotating specialty tools

-

Quick-change systems: Implement easily swappable components

-

Inventory checklists: Develop job-type specific inventories

Many professional painters use removable bins or crates labeled for specific job types. These can be quickly swapped as jobs change, with exterior equipment stored in the shop during interior season and vice versa.

The most sophisticated systems use color-coding to instantly identify job-specific equipment—blue containers for exterior tools, green for interior finishing, for example. This visual system reduces time spent searching for job-specific items by approximately 25%.

What are the best options for organizing spray equipment in a painter's van?

Spray equipment presents unique storage challenges:

-

Cushioned mounting: Protect sensitive components from vibration

-

Hose management systems: Prevent kinking and damage to hoses

-

Tip and guard organization: Secure small components in dedicated containers

-

Cleaning supply proximity: Keep maintenance items near equipment

-

Quick-disconnect planning: Organize for rapid setup and breakdown

For frequent sprayer users, dedicated equipment bays with custom-fitted compartments provide the best protection and accessibility. These typically integrate secure mounting points for the pump unit with adjacent storage for guns, tips, and accessories.

For budget approaches, many painters successfully use padded equipment cases secured to the van floor or wall. The key principle is isolation—spray equipment should be protected from both physical damage and contamination from dust and debris.

How can I maximize the amount of paint I can safely carry?

To optimize paint carrying capacity while maintaining safety:

-

Implement tiered shelving: Utilize vertical space with properly secured shelving

-

Use adjustable dividers: Accommodate different can sizes efficiently

-

Consider weight distribution: Position heaviest items low and centered

-

Install reinforced flooring: Distribute weight loads properly

-

Implement inventory management: Carry what's needed rather than excess stock

Professional paint transport systems can typically increase carrying capacity by 30-50% over generic shelving through space-efficient design. The most effective systems allow for quick reconfiguration to accommodate different container sizes.

Many painters also implement "just-in-time" inventory practices, carrying base materials with on-site tinting capabilities rather than numerous pre-mixed colors. This approach can reduce the required paint storage space by up to 60% while maintaining job readiness.

What security features should I consider for my painter's van organization system?

Security considerations for valuable tools and materials:

-

Lockable compartments: Secure high-value items in dedicated locked storage

-

Stealth storage: Create hidden compartments for valuable items

-

External appearance management: Consider plain exteriors that don't advertise contents

-

Integrated alarm compatibility: Ensure organization systems don't interfere with security

-

Quick-secure features: Implement systems that lock multiple compartments simultaneously

The most comprehensive security approaches combine visible deterrents (quality locks) with non-obvious measures like strategically positioned valuable storage. Many professional painters report that well-organized vans actually improve security by making unauthorized access more noticeable—when everything has a place, disturbances are immediately apparent.

For enhanced security, consider organization systems that integrate with van security features rather than competing with them. Modern systems often include options for electronic locking integrated with vehicle security.

Conclusion: Implementing Your Painter's Van Organization System

A well-organized painter's van is more than a convenience—it's a competitive advantage that impacts every aspect of your business. Proper organization saves time, reduces material waste, extends equipment life, improves job site efficiency, enhances professional image, and ultimately increases profitability.

The ideal organization system balances several key factors: secure paint transportation, efficient tool storage, proper separation of wet and dry materials, ergonomic accessibility, and appropriate weight distribution. Whether you choose professional installation or DIY implementation, the critical factor is creating a systematic approach where every item has a dedicated place.

Begin your organization journey by assessing your specific needs and working patterns. Consider starting with the highest-impact areas—typically paint storage and frequently used tools—and develop a phased implementation plan that allows your system to evolve with your business. Remember that even modest improvements in organization can deliver significant benefits in daily operations.

Your van is more than transportation—it's a workshop, inventory system, and business advertisement combined. Investing in proper organization transforms this essential business asset into a powerful tool for increased productivity and professionalism.