Most electricians waste 15-20% of their workday digging through disorganized vans for the right tool. Your choice between a Transit Custom SWB (Short Wheelbase) and LWB (Long Wheelbase) directly determines whether you're that electrician or the one who shows up prepared and finishes jobs faster.

Whether you're a solo spark just starting out or managing a growing electrical company, your van's cargo space impacts everything - job completion times, customer satisfaction, and profit margins. Pick wrong, and you'll burn money on wasted fuel, missed opportunities, and frustrated clients waiting for return trips to fetch forgotten gear.

This comparison cuts through the marketing fluff to show you the real differences between Transit Custom SWB and LWB models, focusing specifically on electrical work demands. You'll discover exact storage capacities, true operating costs, and which variant matches your business stage and job types.

Quick Answer for Busy Electricians

Transit Custom SWB offers 2.6m load length suitable for basic electrical toolkits, while LWB provides 3.0m with significantly more payload capacity.

LWB models increase cargo volume by 15-22% and typically retain higher resale values, making them ideal for growing electrical businesses despite the £1,500-£2,000 initial premium.

LWB Gives You 40cm More Length (Plus Hidden Benefits)

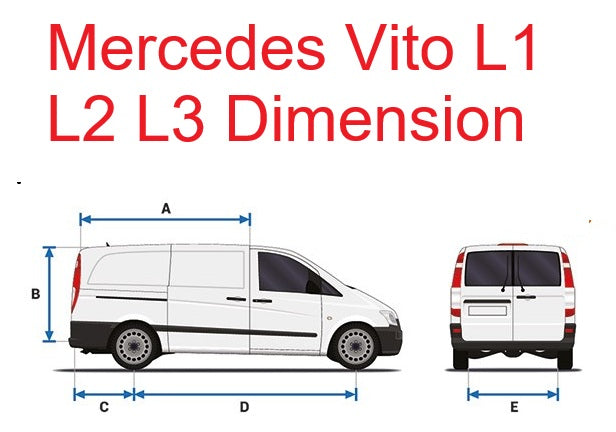

The Transit Custom SWB delivers 2.6m of internal load length, while the LWB stretches to 3.0m - that extra 400mm makes a massive difference for electrical kit organization. Both variants share identical 1.43m load height and 1.39m width between wheel arches, so your choice boils down to whether you need the extra length.

Why Those Extra 40cm Matter More Than You Think

The SWB's 2.6m internal length works fine for basic electrical hand tools and standard power tool cases. But longer items like cable reels, conduit lengths, and testing equipment quickly push these limits. I've watched electricians cram 2.8m cable reels diagonally in SWB vans, damaging both the reel and van interior.

LWB's extra 400mm eliminates this problem entirely. You can store 2.8m cable reels flat, keep trunking straight, and organize longer tools without playing van Tetris. The consistent 1.43m height across both variants accommodates standard electrical equipment racks without modification.

Width remains unchanged at 1.39m between wheel arches for both models. This standardization means shelving systems designed for Transit Customs fit identically regardless of length choice.

Payload Capacity: LWB Carries 300kg More

Here's where LWB really shines for electrical work: cargo volume jumps from 5.4-6.6m³ (SWB) to 6.2-7.7m³ (LWB) depending on roof configuration. That represents a 15-22% volume boost that directly translates to better organized storage space.

According to manufacturer specifications, payload capacities range from 970kg up to 1,469kg depending on specific variant and equipment levels. LWB models typically offer higher payload ratings within each trim level, giving you more capacity for heavy electrical equipment like transformers and cable drums.

The volume difference becomes critical when you consider that modern electrical toolkits require 4-5m³ of organized storage. SWB vans operate near capacity limits from day one, while LWB models provide breathing room for business growth.

Electrical Kit Storage: What Actually Fits Where

Professional electrical work demands specific storage solutions that basic van layouts can't handle. After analyzing dozens of electrical contractor setups, the space requirements break down predictably across tool categories.

Your Complete Electrical Toolkit Needs 4-5m³ Minimum

A functional electrical toolkit needs minimum 4-5m³ of organized storage space to work efficiently. This breaks down into:

- Hand tools: 0.5m³

- Power tools: 1m³

- Materials storage: 3-4m³

- Cable reels and conduit: 2m+ uninterrupted length for proper storage

Most electricians underestimate material storage requirements. A typical domestic rewire demands multiple cable types, junction boxes, switches, sockets, and safety equipment. Without proper organization, you'll spend valuable time searching for tools during jobs.

SWB vans can accommodate basic electrical toolkits, but they require careful planning and compromise. You'll often choose between carrying extra cable or additional testing equipment - rarely both. According to van shelving specialists, typical domestic callouts use approximately 60% of SWB storage, leaving little room for unexpected requirements or business expansion.

Industrial Equipment Pushes SWB Beyond Limits

Industrial testing equipment cases and emergency response kits quickly max out SWB storage capacity. Cable ladders and trunking require 2.5m+ uninterrupted storage length - impossible in SWB without diagonal placement that damages expensive equipment.

LWB's additional 400mm enables proper storage of specialized gear that SWB vans simply can't accommodate safely. I've seen expensive PAT testing equipment damaged from improper storage in cramped SWB setups. The extended cargo space can reduce tool search time significantly during jobs, directly improving productivity.

Emergency callout kits benefit enormously from LWB organization. When you're responding to power failures at 2 AM, having dedicated storage bays for emergency lighting, temporary supplies, and safety equipment makes the difference between professional service and frustrated fumbling in the dark.

Van Shelving: SWB Forces Compromises, LWB Enables Growth

Shelving systems make or break van efficiency, and size choice dramatically affects your options. Both SWB and LWB Transits accept custom shelving, but the configurations differ significantly.

SWB: Maximum Efficiency in Minimal Space

SWB models optimally support 3-tier shelving systems within the 2.6m load length. Side shelving works well within the 1.39m width constraints, providing secure storage for electrical components and testing instruments. Drawer systems fit neatly for sensitive equipment needing protection from vibration and theft.

The compact footprint forces prioritization - you'll install shelving for essential items only. Most SWB electrical setups focus on frequently used tools and basic materials, storing specialty items in secure toolboxes that consume valuable floor space.

LWB: Room for Proper Workshop Organization

LWB models accommodate 4-tier shelving configurations thanks to the extra 400mm length. This seemingly small difference enables mobile workbench installation for van-based repairs and equipment maintenance. Extended floor space allows proper storage of longer items without compromising shelving density.

The significantly greater storage density that LWB shelving provides becomes crucial for growing electrical businesses. You can store complete toolkits for multiple electricians, apprentice equipment, and safety gear in a single vehicle. This consolidation reduces fleet costs while improving job flexibility.

Real Numbers: What LWB Actually Costs vs What You Get

The LWB premium averages £1,500-£2,000 over equivalent SWB specifications, but this upfront cost only tells part of the financial story. Long-term value calculations often favor LWB models for serious electrical operations.

Operating Costs: The £200-400 Annual Fuel Penalty

Fuel consumption increases with LWB configurations due to additional weight and aerodynamic drag. WLTP testing demonstrates this difference: short-wheelbase Transit Custom L1H1 models achieve 38.7-40.9 mpg combined, while long-wheelbase L2 variants deliver 36.2 mpg in independent testing. This 2-4 mpg differential—consistent with Ford's official efficiency data—translates to approximately £200-400 in additional annual fuel costs for commercial operators covering 15,000 miles.

Insurance premiums remain similar between variants for commercial electrical use, as insurers focus more on vehicle security and operator history than wheelbase length. The higher purchase price often concerns new electrical contractors, but financing spreads this cost over several years. When weighed against improved efficiency and reduced material runs, LWB models typically pay back their premium within two years.

Resale Reality: LWB Holds Value Better

LWB Transit Customs tend to retain higher resale values over five years due to versatility demand in the used commercial vehicle market. The exact difference varies with market conditions, but LWB's broader appeal to different trades supports stronger residual values.

Expanding electrical businesses benefit enormously from LWB's scalable storage capacity - you won't outgrow the van as quickly. Professional appearance matters more than many electricians realize. Well-organized LWB shelving systems project competence to customers and support higher pricing for premium services.

Which Van Fits Your Electrical Work Type?

Different electrical work demands different van configurations. Understanding your primary job types helps determine the right Transit Custom size.

Domestic Work: SWB Handles Most Residential Jobs

Residential electrical work fits comfortably within SWB storage parameters for most standard jobs. Typical domestic callouts use approximately 60% of available SWB capacity, leaving room for unexpected requirements. SWB's maneuverability advantages shine in residential driveways and narrow streets where LWB models struggle.

House rewires, socket additions, and fault-finding work require standard electrical toolkits that SWB vans accommodate easily. The fuel efficiency advantage becomes significant for electricians covering urban areas with frequent stop-start driving patterns.

However, SWB limitations appear during larger residential projects like full house rewires or multi-property contracts. You'll make additional material runs that LWB operators avoid, increasing project time and fuel costs.

Commercial/Industrial: LWB Becomes Essential

Commercial electrical work demands 80-90% of LWB storage capacity utilization. Multi-day industrial installations require extensive material storage that SWB vans simply can't provide. Cable pulling equipment, industrial testing gear, and safety equipment for confined spaces need dedicated storage areas.

Apprentice tool storage and additional safety equipment strongly favor LWB configurations. Training programs benefit from standardized LWB fleet vehicles that accommodate both supervisor and apprentice toolkits safely.

Industrial electrical contracts often specify response times that make material availability critical. LWB vans enable contractors to carry comprehensive spare inventories, reducing costly delays when specialized components fail.

Decision Framework: Pick Based on Business Reality, Not Price

Selecting between SWB and LWB depends on business stage, growth plans, and primary job types. This framework helps electricians make informed decisions rather than emotional ones.

New vs Established Business Considerations

Solo electricians starting residential work might consider SWB for initial cost optimization, especially if capital is limited. The lower purchase price, reduced insurance costs, and better fuel economy support new business cash flow requirements.

However, many new electricians who initially select SWB upgrade to LWB within three years as business grows. This pattern suggests that early SWB adoption often becomes false economy when upgrade costs are considered.

Partnership arrangements and employee scenarios require LWB storage for multiple toolkit accommodation. You can't efficiently share SWB space between two electricians without constant reorganization and compromise.

Geographic and Job Type Analysis

Urban domestic electrical services favor SWB maneuverability and parking advantages in congested city centers. The fuel efficiency benefits compound with frequent short-distance jobs and stop-start driving patterns.

Rural and commercial electrical coverage benefits from LWB's extended range capabilities and comprehensive tool storage. When job sites are 30+ miles apart, carrying complete equipment inventories prevents costly return trips for forgotten items.

Mixed residential/commercial electrical work requires LWB versatility for optimal efficiency. The ability to handle diverse job requirements from a single vehicle platform improves scheduling flexibility and customer service levels.

Ready to optimize your van storage? Browse our Transit Custom SWB shelving solutions or explore LWB storage systems designed specifically for electrical contractors. Visit our Ford van racking collection to find the perfect storage solution for your business needs.