The van dimension codes scattered across every spec sheet aren't just manufacturer jargon - they're the secret language that determines whether your next van purchase will actually work for your business or leave you scrambling for expensive modifications.

While an estimated 4.6 million licensed vans navigate British roads daily, most buyers still struggle to decode what L1H1, L2H2, or L3H3 actually means for their daily operations.

These standardized European classifications directly impact everything from your daily cargo capacity to which car parks you can access, making them essential knowledge before you sign any lease agreement. Understanding these codes saves you thousands in retrofitting costs and prevents the frustration of discovering your new van doesn't fit your actual storage needs.

TL;DR: The Essential Van Code Breakdown

Van codes like L1H1, L2H2, L3H3 define standardized European length (L) and height (H) categories across all manufacturers.

L2H2 configurations are widely popular among UK trades due to their optimal balance of cargo space and maneuverability, while professional shelving systems can boost storage efficiency by up to 50%.

Van Dimension Codes: The Universal System Every Trade Professional Needs

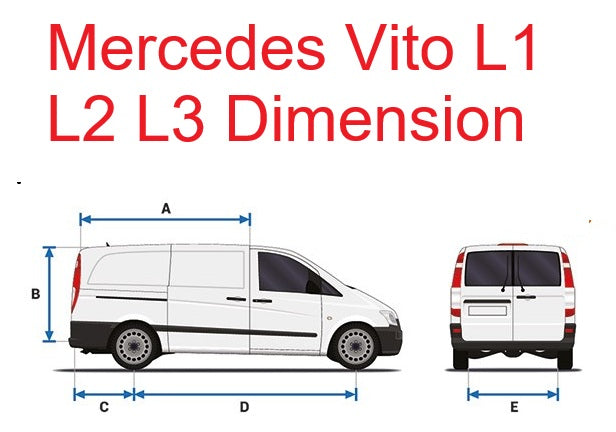

Van dimension codes represent the standardized European classification system that defines vehicle size categories across all major manufacturers. These two-part codes determine your van's cargo capacity, which directly impacts how much equipment and materials you can carry daily.

The system uses standardized load planning and comparison across all major brands, making it easier to evaluate options from Ford, Mercedes, Volkswagen, and other manufacturers.

Understanding these dimensions proves essential before investing in van racking systems, as storage solutions must match your specific size category to maximize efficiency.

How the Two-Part Code System Works

- The first part (L1, L2, L3, L4) indicates length categories, with L1 being shortest and L4 being extra-long wheelbase options.

- The second part (H1, H2, H3) represents height categories, ranging from standard roof height to high-top configurations.

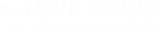

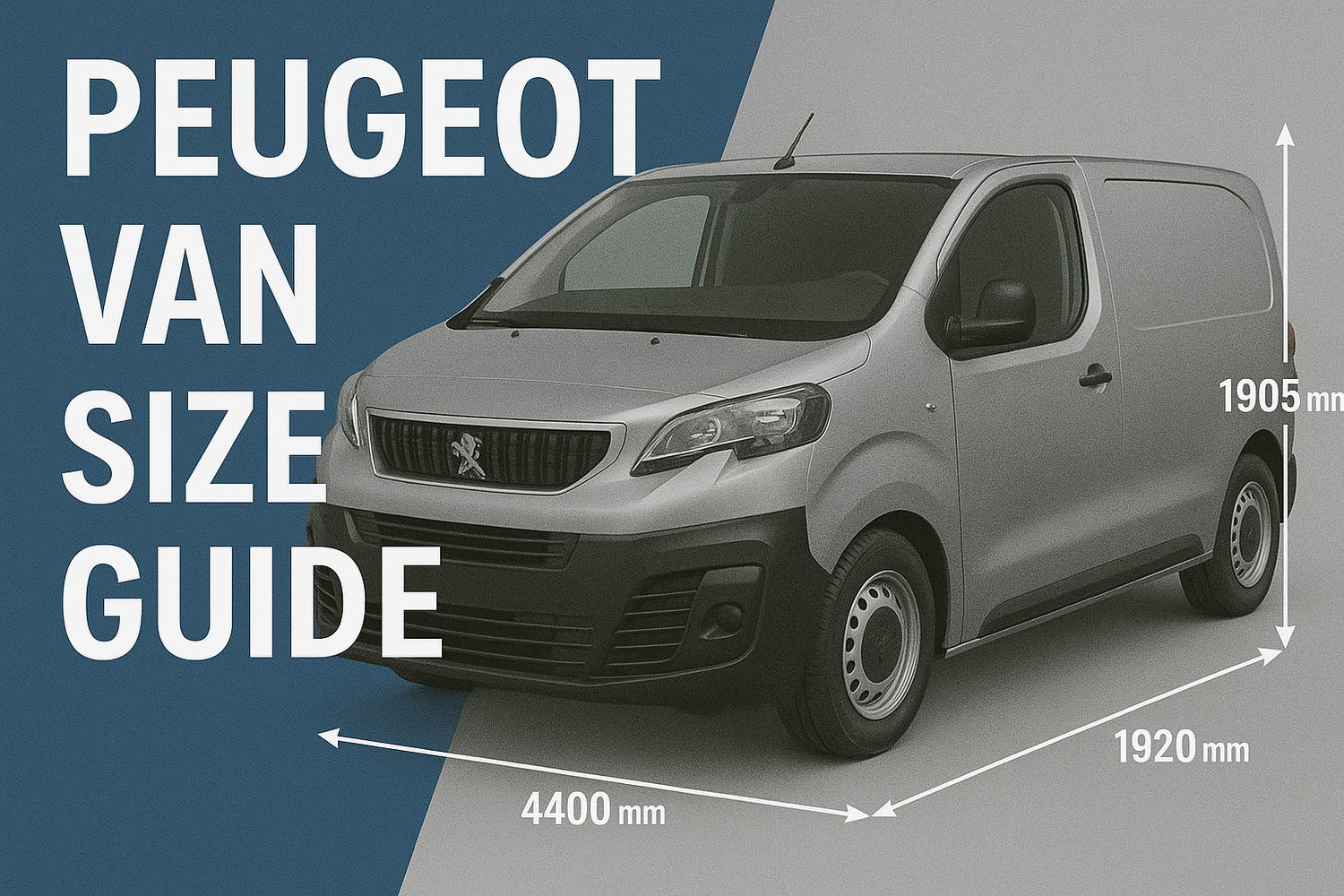

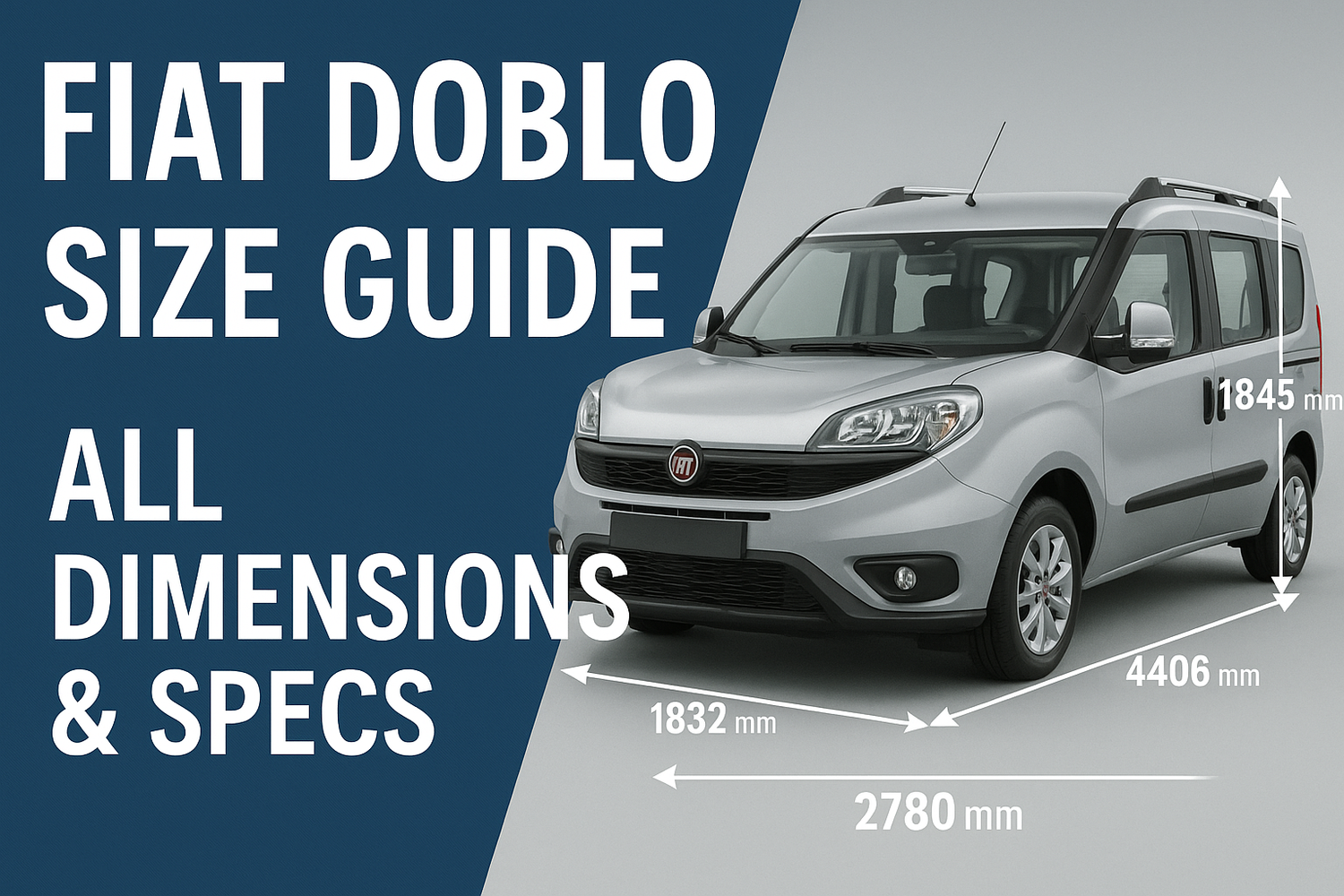

All major UK manufacturers - Ford, Mercedes, Volkswagen, Peugeot, Renault, Citroën - use this universal L/H system, enabling consistent comparison across different brands and model years.

This standardization means once you understand the codes, you can confidently evaluate vehicles regardless of manufacturer.

Length Classifications: L1 Through L4 Define Your Cargo Reality

L1 (Short Wheelbase): Compact Efficiency for Urban Operations

L1 vans typically measure 4.6-5.4 meters in total length with cargo areas around 2.5-3.0 meters long. These compact vans excel in city driving, tight parking situations, and businesses requiring frequent stop-start operations.

Load capacity ranges from 5-6 cubic meters depending on height configuration, suitable for tool-heavy trades with lighter materials.

L1 models are commonly chosen by electricians and maintenance contractors working urban routes due to their superior maneuverability in restricted access areas.

L2 (Medium Wheelbase): The Sweet Spot for Most UK Trades

L2 vans measure approximately 5.4-6.0 meters total length with cargo areas extending 3.1-3.7 meters. This category offers the best balance of maneuverability and storage capacity for plumbers, electricians, and general contractors.

Load volumes typically range 8-11 cubic meters, accommodating both extensive tool collections and moderate material loads. The L2 segment represents a significant portion of trade van sales due to this versatility.

L3 (Long Wheelbase): Serious Space for Growing Operations

L3 vans stretch 6.0-7.0 meters total length with cargo areas reaching 3.5-4.1 meters for substantial storage. These vans suit businesses requiring material transport like kitchen fitters, flooring contractors, or multi-trade operations.

Cargo volumes can reach 13-14 cubic meters, though maneuverability in urban areas becomes more challenging. Multi-trade contractors commonly choose L3 configurations when needing maximum storage capacity.

L4 (Extra Long): Maximum Capacity for Specialist Requirements

L4 vans exceed 7.0 meters with cargo areas reaching 4.2-4.7 meters for maximum possible storage. These represent the largest standard commercial vehicle category before requiring commercial driving licenses.

Load capacity can exceed 15-17 cubic meters, making them suitable for businesses with substantial material requirements or mobile workshop conversions.

Height Classifications: H1, H2, H3 Determine Your Vertical Storage Strategy

H1 (Standard Height): Low Profile for Universal Access

H1 vans maintain heights under 2.0 meters, ensuring access to most residential driveways and standard car park barriers. Internal cargo height typically measures 1.4-1.6 meters, sufficient for most hand tools and standard equipment storage.

These configurations offer better fuel economy and handling characteristics compared to taller alternatives, making them popular for urban fleet applications where access restrictions are common.

H2 (Medium Height): Balanced Headroom for Practical Working

H2 configurations reach 2.1-2.5 meters external height with internal cargo heights around 1.7-1.9 meters. This height allows limited standing access for average-height individuals while maintaining reasonable fuel efficiency.

Van racking installations are commonly specified for H2 configurations due to the practical working height. The partial standing headroom proves beneficial for contractors who work from their vans throughout the day.

H3 (High Roof): Maximum Vertical Space for Full Standing Room

H3 vans exceed 2.5 meters height with internal cargo areas reaching 2.0+ meters for full standing room. These configurations accommodate tall equipment, extensive shelving systems, and provide comfortable working space inside the vehicle.

Mobile workshop conversions frequently specify H3 height for full standing room capability. This configuration proves essential for businesses transporting ladders, pipes, timber, or requiring mobile workshop functionality.

Real-World Load Capacity: How Dimensions Translate to Practical Storage

Different van configurations offer dramatically different storage capabilities:

- L1H1 combinations: 5-6 cubic meters, suitable for compact tool collections

- L2H2 configurations: 8-11 cubic meters, accommodating comprehensive trade setups

- L3H3 setups: 13-15 cubic meters for substantial equipment and materials

- L4H3 maximum: Up to 17 cubic meters for largest possible loads

Professional van shelving increases load efficiency by up to 50% compared to basic storage approaches, making organization systems a worthwhile investment.

Weight Distribution and Legal Load Limits You Must Know

UK van weight limits typically range 2.8-3.5 tonnes gross vehicle weight regardless of size category. Larger dimensions don't automatically mean higher weight capacity, making strategic loading essential for compliance.

Overloading fines range from £100 to £5,000+, making proper weight management essential. Professional van racking systems typically add 40-80kg but can increase effective storage capacity by 30-50% through better organization.

Choosing the Right Size: Matching Van Dimensions to Your Actual Trade Requirements

Assessing Your Daily Equipment Needs

For electricians: L1H2 or L2H2 configurations typically work well for cable reels, testing equipment, and comprehensive tool collections.

For plumbers: L2H2 or L2H3 setups accommodate pipe lengths, water heaters, and bulky bathroom fixtures effectively.

For general contractors: L3H3 configurations often provide the diverse tool requirements and material transportation capabilities needed.

For specialist trades: L4H3 may be necessary for businesses with exceptional storage requirements or mobile workshop needs.

Future-Proofing Your Van Investment Strategy

Consider potential business growth when selecting dimensions, as upgrading later involves significant costs and downtime. Evaluate whether your regular job sites can accommodate larger van dimensions before committing to L3 or L4 length categories.

Factor in parking restrictions, height barriers, and urban access requirements specific to your operating area. A van that can't access your customer locations defeats the purpose of extra storage space.

Cost Considerations Across Size Categories

Based on current market data, larger vans typically cost £3,000-8,000 more than compact alternatives in purchase price and insurance premiums. Fuel consumption generally increases 10-15% moving from L1H1 to L3H3 configurations due to aerodynamic and weight factors.

Van shelving system costs scale with size, with L3H3 installations costing 40-60% more than L1H1 equivalents. However, increased productivity and professional appearance often justify this investment through improved efficiency and customer confidence.

Van Shelving Implications: How Dimensions Shape Your Storage System Design

Shelving Configuration Options by Size Category

L1 vans: Accommodate 2-3 vertical shelving bays with limited floor storage for secure boxes or drawers

L2 vans: Support 3-4 shelving sections plus dedicated areas for longer tools and materials

L3/L4 vans: Enable comprehensive storage solutions with 4-6 shelving bays and separate zones for different equipment types

Modular van racking increases effective tool storage significantly and reduces tool search times, leading to more productive site visits.

Access and Organization Strategies That Actually Work

H1 height: Requires sliding drawer systems for accessing rear shelving areas efficiently

H2 configurations: Allow standing access to middle shelving levels while requiring step access for top sections

H3 vans: Enable full-height shelving systems with comfortable access to all storage levels

Custom Racking Solutions for Each Configuration

Professional van shelving systems must account for wheel arch intrusions, door openings, and load floor height variations. Lightweight steel/aluminum shelving reduces total van weight compared to wood alternatives while providing superior durability.

Modular racking systems offer flexibility to reconfigure storage as business requirements change over time. Quality shelving installations can increase effective storage capacity by 35-50% compared to basic approaches while maintaining compliance with legal weight limits.

Ready to optimize your van's storage potential? Explore our complete range of van shelving solutions designed to match your specific L/H configuration, or browse our stock racking systems to find the perfect fit for your trade requirements.