Many UK tradespeople end up replacing their entire van fit-out when business requirements change, often wasting substantial investment. 4.6 million licensed vans operate across Britain, yet most still use fixed timber shelving that becomes obsolete the moment job requirements shift.

Whether you're an electrician expanding into plumbing work or a builder adding HVAC services, rigid storage systems often lead to expensive complete replacements instead of simple adaptations.

Modular van shelving systems solve this costly problem by using reconfigurable components that adapt to evolving business requirements without requiring system replacement. According to Dataintelo, the global van shelving systems market is projected to grow from USD 2.35 billion in 2024 to USD 4.39 billion by 2033, with modular systems as a key driver.

These flexible systems allow most components to be reused across multiple layout changes and vehicle upgrades, whereas plywood installations often have to be discarded or rebuilt for each new van.

What Makes Van Shelving "Modular" and Worth the Investment?

Modular van shelving systems feature reconfigurable components like adjustable shelves, movable dividers, and interchangeable accessories that adapt to evolving business requirements without requiring complete system replacement.

Many businesses recover the cost within about a year through time savings, reduced damage, and improved organisation.

Core Modular Components That Actually Work

Modular van shelving systems consist of interchangeable base frames, adjustable shelf brackets, and removable dividers that can be repositioned without tools. Unlike fixed systems where shelving positions are permanently installed, modular designs allow individual components like tube holders, drawer units, and toolbox mounts to be added, removed, or relocated as business needs change.

VanShelves offers modular accessories such as:

- 12-tube sealant holders

- Aerosol can holders

- Racking toolbox holders

- Volt Slider small drawers

These components bolt to standard racking frames using pre-punched side panels with vertical slots typically spaced at 50mm intervals, enabling shelves and dividers to be repositioned in precise increments to match changing storage needs.

As VanShelves explains, "Shelving modules, drawers, and accessory panels share a common hole pattern and mounting system, making it easy to mix, match, and move components as your requirements change."

Tool-Free Reconfiguration in Under an Hour

Most modular van shelving systems can be reconfigured in under an hour using basic hand tools or tool-free adjustment mechanisms. VanShelves reports that customers can assemble complete racking systems in less than two hours, meaning partial reconfigurations typically require a fraction of that time.

The reconfiguration process involves loosening mounting brackets, repositioning components, and retightening connections without drilling new holes or permanent modifications. Commercial Vehicle Contracts notes that van racking is increasingly designed for DIY installation and can usually be fitted or adjusted in a few hours.

Why Small Businesses Desperately Need Adaptable Storage

Small businesses experience frequent inventory changes, seasonal equipment variations, and service expansion that demand flexible storage solutions.

A plumbing business may need more pipe storage in winter and additional small parts organisation during busy repair seasons. Modular systems accommodate these shifts without requiring expensive van conversions or complete shelving replacements.

Business Growth Demands Storage That Evolves

Growing businesses can add specialised storage modules, increase carrying capacity, or incorporate new tool categories without disrupting existing organisation. Tecnolam UK observes, "Trade professionals' needs change over time – new tools, different materials, and expanding services – so flexible van racking that can grow with the business is essential."

The same modular product range is marketed to electricians, plumbers, carpenters, mechanics and general builders, changing mainly the accessory mix rather than the core frames. This versatility maximises vehicle utilisation for businesses offering diverse services.

Seasonal Variations Require Layout Flexibility

Many trades show seasonal patterns, affecting what tools and materials are carried. As Accio notes, "As seasons change, so do the tools and materials your technicians carry. A modular storage system lets you adjust shelving, bins, and cases to match seasonal tasks without buying a new fit-out."

HVAC contractors need more refrigerant storage during summer months and heating component space in winter. VanShelves describes how racking helps companies keep tools for different types of work separate, giving the example of trades using shelving to organise equipment for "different jobs and different times of the year."

The Real Cost of Fixed Systems

VanShelves' cost guide shows typical full van shelf systems ranging from around £400-£1,200+ depending on configuration. Fixed systems require professional removal, new component purchases, and reinstallation for changes, often costing £800-1,500 per reconfiguration. Pre-configured van shelving packages can save customers up to £250 compared with fully bespoke designs while still offering modularity.

As Van Care explains, "Aluminium and steel van racking lasts longer and can be transferred between vehicles, which means lower long-term costs compared to wooden racking that may need replacing with every van."

How Reconfigurable Layouts Work in Real Situations

Standard modular components include adjustable shelves with 2-inch increment positioning, removable tube holders accommodating 12 sealant tubes, sliding drawer units, and detachable toolbox mounts. Research on modular storage design shows that well-engineered setups rely on a limited number of fixed mounting points, so most reconfiguration simply involves repositioning shelves and accessories rather than drilling new holes.

Universal Mounting Makes Changes Simple

Modul-System UK describes how "Our lightweight van shelving uses modular aluminium profiles and universal fittings so that shelves, drawer units, and cases can be reconfigured or expanded at any time."

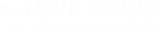

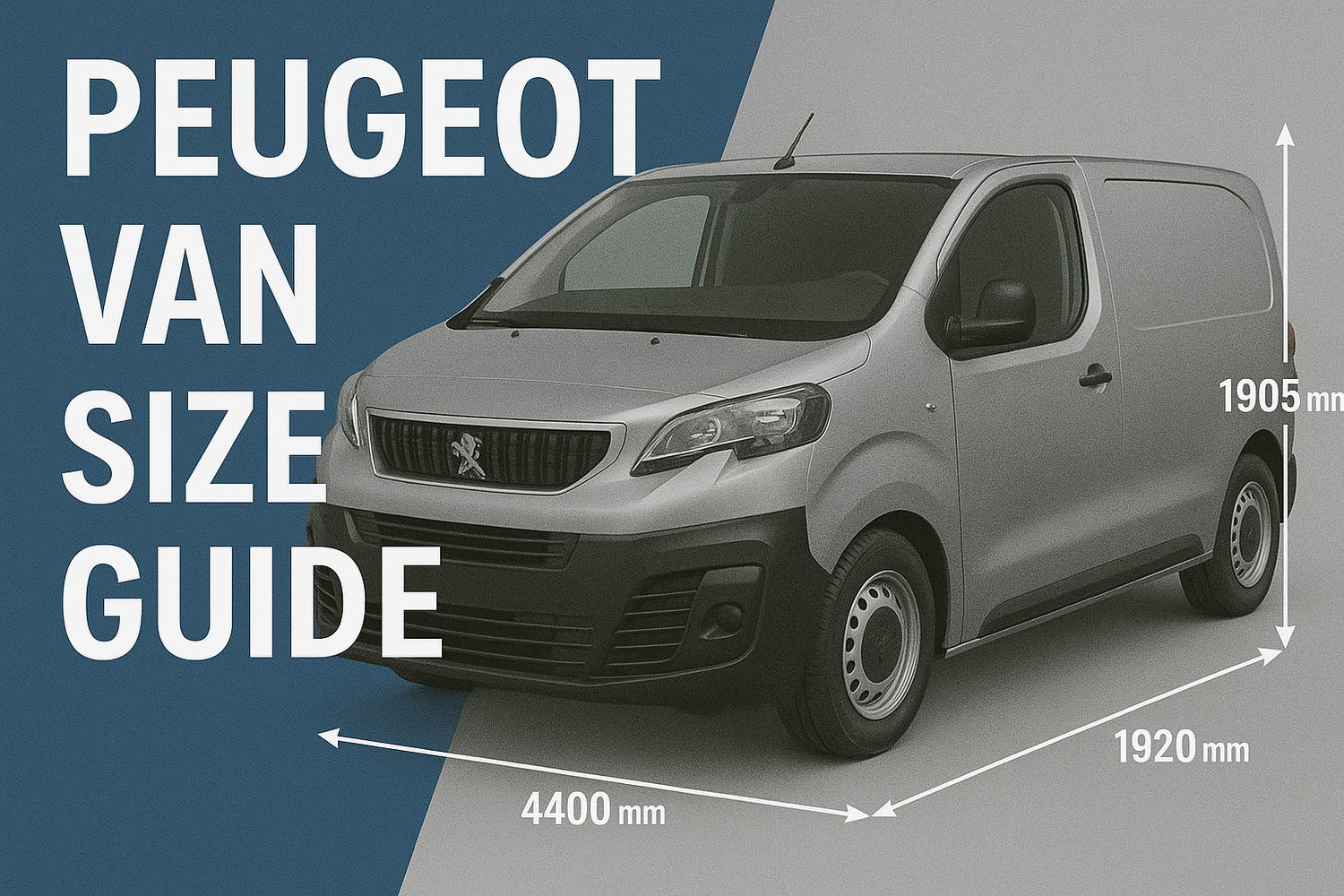

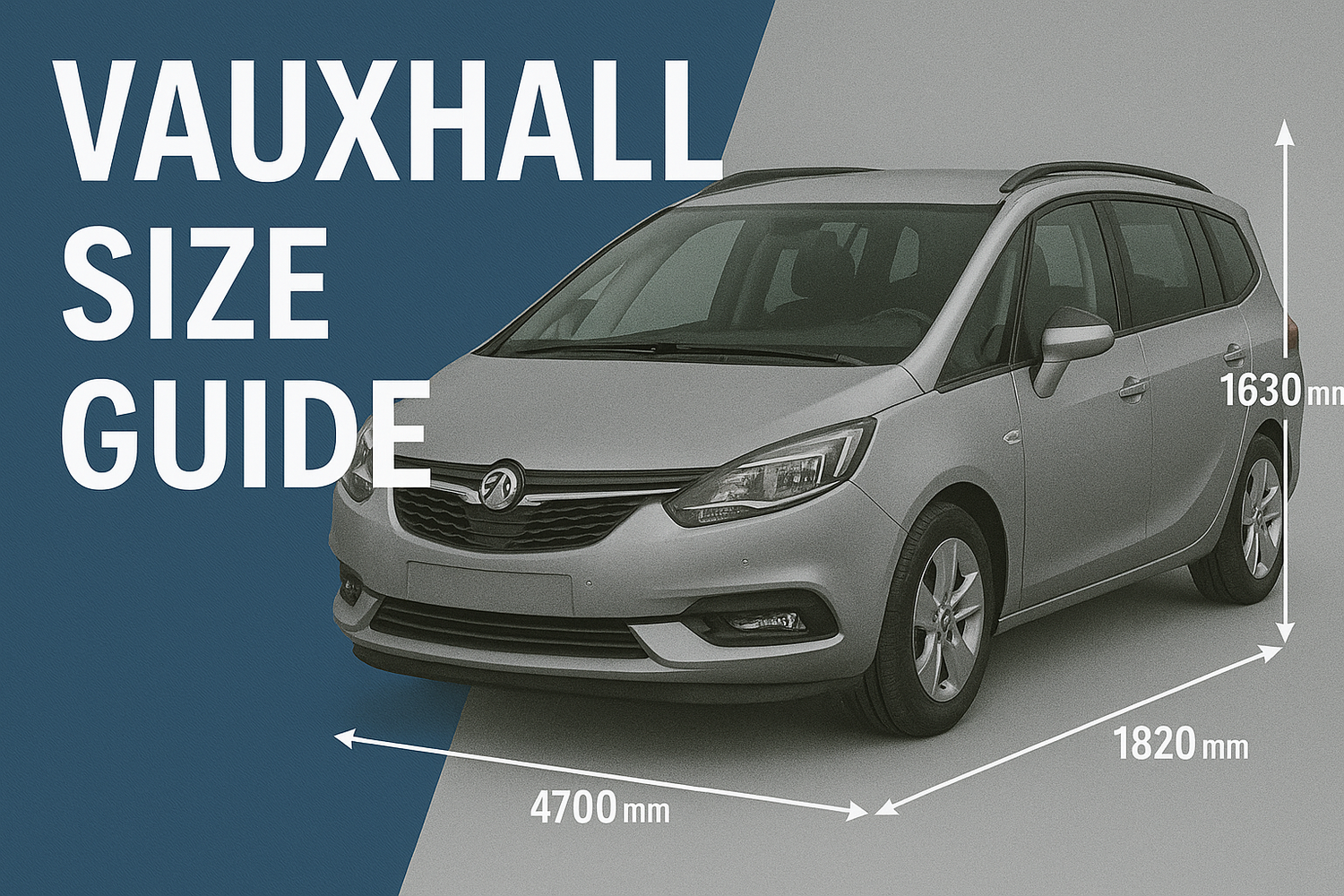

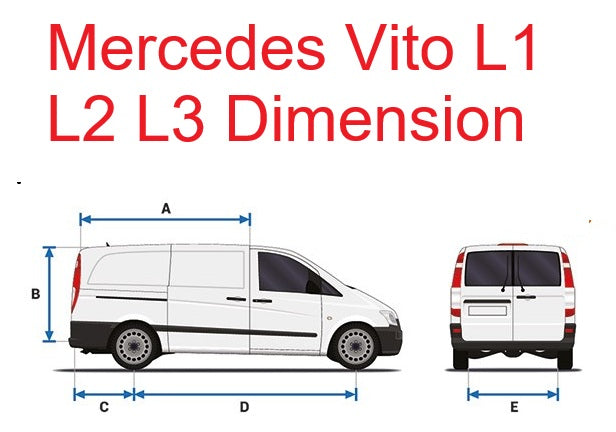

These components connect through universal mounting systems that maintain structural integrity across different configurations. VanShelves' product range shows the same racking side frames used across different Transit, Vivaro, Dispatch and other van models, with customers choosing combinations of shelves, tube holders and drawers that can be expanded later.

Real Electrician-to-Plumber Conversion Example

A typical electrician-to-plumber reconfiguration involves:

- Moving tube holders from upper shelves to lower positions

- Replacing narrow parts drawers with wider pipe storage

- Repositioning toolbox mounts for heavier equipment

- Adding more tube storage and different bin modules

VanShelves features customers who fitted racking into Transit Customs, using lower shelves for heavy tools, mid-level shelves for parts, and upper sections with tube holders. The same base kit can be adapted for plumbing by adding more tube storage and different bin modules while keeping the framework.

This transformation typically takes under an hour and requires no additional van modifications. Many racking manufacturers publish trade-specific layouts (electrician, plumber, builder, courier) built on the same core shelving products, demonstrating that trade-to-trade conversion mainly involves swapping accessories.

Key Advantages Over Fixed Shelving That Actually Matter

Metal modular racking is often reused across several vehicles and can outlast the van, while plywood setups are usually scrapped or rebuilt at each van change. When businesses upgrade vehicles, modular components transfer to new vans with minimal adaptation requirements.

Investment Protection Through Reusability

The van shelving systems market is driven by businesses' willingness to invest in durable, reusable systems that can be moved between vehicles instead of one-off custom builds.

VanShelves emphasises that its products are built from durable materials and designed to fit multiple vans, with repeat customers noting they "would definitely buy again" and plan to use the racking across future vans. Commercial Vehicle Contracts reports that businesses fitting quality racking experience less interior damage and can achieve better residual values at defleet.

Productivity Gains From Better Organisation

According to Truck in Thunder, organised shelving can save 30-45 minutes per technician per day, equating to several extra billable hours per week. VanShelves cites research suggesting that optimised hand-tool organisation reduces repair time variability by around 40% and improves first-time fix rates.

The ability to reconfigure storage layouts for specific projects ensures frequently used items remain easily accessible. Customer reviews highlight improved organisation: "Great quality racking! Easy to install, sturdy, and has really helped organize my tools."

Weight Savings That Reduce Running Costs

Lightweight aluminium and steel racking systems can be 5-9 kg lighter per bay than traditional heavier alternatives. Research shows that every 100 kg of additional vehicle weight increases fuel consumption by approximately 0.7 litres per 100 km; for electric vans, additional payload reduces range by 3-8%, so lightweight modular racking maintains operational efficiency and preserves battery range.

With UK LCV registrations totalling 156,048 units in H1 2025 and electric LCV adoption reaching 7.6% share, racking must increasingly be compatible with new vehicle platforms while minimising weight penalties.

Choosing the Right Modular System Without Overspending

Key selection criteria include component compatibility across different configurations, weight capacity for heaviest anticipated loads, and installation complexity for routine reconfigurations. VanShelves provides pre-configured kits for specific vans with detailed product pages specifying dimensions, shelf count, and included accessories.

Assessment Criteria That Actually Matter

Businesses should evaluate whether the modular system supports their specific trade requirements, offers necessary accessories, and provides clear reconfiguration instructions. Tecnolam UK advises, "When choosing van racking, think about your trade, the weight of your tools, and how often you'll need to change your layout. Modular systems that can be adjusted without specialist tools offer more flexibility."

Essential considerations:

- Crash-tested racking with clearly rated load capacities

- Universal hole patterns for future expansion

- DIY-friendly installation and adjustment

- Compatibility with existing van equipment

Independent safety coverage reports that most major van racking suppliers now crash-test their systems to ECE R17.07 and similar standards to ensure shelving and drawer units remain secure under collision loads, while racking safety guidelines emphasise clearly defined load limits for each shelf and drawer to prevent overloading and structural failure.

Integration With Your Current Setup

Quality modular systems integrate with existing van equipment through universal mounting points and adjustable clearances that accommodate pre-installed features. Commercial Vehicle Contracts notes that "Good van racking works with your van's wheel arches, doors, and lighting, not against them."

The systems should work around wheel wells, lighting fixtures, and door mechanisms without compromising accessibility or safety. Proper integration maintains full van functionality while maximising storage efficiency across all configurations.

Return on Investment Reality Check

Depending on labour rates and van usage, many businesses recover the cost of racking within about a year through time savings, reduced damage and fewer lost tools. Van racking protects the van interior, meaning higher resale values and lower repair costs, with fleets reporting reduced damage to bodywork and trims from loose tools and materials.

The calculation becomes compelling when you consider that racking helps prevent van overloading fines (ranging from £100 to over £5,000) by making it easier to distribute and secure loads.

By enabling one van to cover multiple roles, modular racking can reduce the need for extra vehicles, avoiding the capital and running costs of another van while maintaining operational efficiency throughout growth phases.

Ready to transform your van into a flexible, productive mobile workspace? Explore VanShelves' complete range of modular van shelving systems and discover how reconfigurable storage can adapt to your changing business needs while protecting your investment for years to come.