For UK businesses looking to maximize mobile storage, professionally installed van shelving systems can increase the load area, with extra-long wheelbase (ELWB) vans delivering significantly more shelving capacity than standard configurations, especially when combined with folding shelves for flexible loading.

Fleet operators face mounting pressure to optimize storage efficiency while maintaining vehicle compliance and operational costs.

This guide examines the top ELWB models available in 2025, analyzing cargo volumes, payload capacities, and shelving optimization potential.

With 4.6 million licensed vans operating across Great Britain and ELWB registrations representing 28% of total LCV sales, choosing the right platform directly impacts productivity and profitability for growing businesses. Professional three-tier shelving creates 40-55 linear meters of organized storage space in most ELWB configurations.

What You'll Discover in This Guide

- Ford Transit ELWB delivers 15.1m³ with up to 1,630kg payload

- Mercedes Sprinter ELWB provides 15.5m³ with excellent structural integrity

- Iveco Daily ELWB offers 17.5m³ with commercial-grade chassis design

- Professional shelving ROI typically pays back in 14-18 months

- Weight distribution affects compliance and £100-£5,000+ overloading fines

Understanding ELWB Van Architecture

Extra long wheelbase vans feature platforms up to 4,500mm between the axles, compared to standard 3,000-3,500mm wheelbase models. According to independent road tests, these extended variants deliver maximum cargo volumes ranging from 14.8 to 18.4 cubic metres (compared to 8-12m³ for standard models), representing a 40-50% increase in shelving and storage installation potential for trade and fleet users.

Extra-long wheelbase (ELWB) and large vans are experiencing significant commercial uptake across the UK, with the largest van segment now representing almost 7 in 10 (68.9%) of all LCV registrations, reflecting growing demand for capacity solutions. The architecture of ELWB models differs significantly from standard vans—manufacturers extend the load floor behind the rear axle, creating uninterrupted cargo space without structural intrusions, which provides ideal conditions for professional van shelving installation.

Weight distribution becomes more complex in ELWB configurations. Professional shelving installations must calculate weight per linear meter to prevent overloading individual mounting points. The extended rear overhang affects handling characteristics, making proper load placement critical for safety and compliance.

Maximum payload capacities range from 1,400kg to 2,500kg depending on chassis configuration and GVW ratings. Professional shelving systems add 45-85kg weight while increasing usable storage capacity by up to 60%. Every additional 100kg of unnecessary weight reduces fuel economy by approximately 1-2%, making lightweight aluminum systems increasingly popular for fleets seeking to optimize both payload and fuel efficiency.

Key ELWB Benefits for Commercial Operations

- 40-50% more shelving installation space than standard wheelbase

- Uninterrupted load floors without wheel arch interference

- Extended reach for ladder and pipe transport

- Higher resale values when properly equipped with quality shelving

Ford Transit ELWB: The UK Fleet Favorite

The Ford Transit ELWB delivers 15.1m³ cargo volume with 4,972mm internal load length and 1,780mm width. Maximum payload reaches 1,630kg with standard panel van configurations. The flat floor design accommodates full-height shelving systems up to 1,950mm without wheel arch interference.

Transit ELWB models support up to 52 linear meters of shelving across both sidewalls and rear bulkhead installations. Three-tier shelving systems maximize vertical space utilization while maintaining 400mm minimum shelf depth for tool storage. Side door access means mid-van loading without rear door operation requirements.

The 350 ELWB model offers optimal payload-to-capacity ratio at 1,805kg maximum load with adequate shelving weight allowance for lighter installations. Both configurations feature tie-down points every 500mm for secure shelving mounting.

Ford Transit ELWB Real-World Performance

Ford's approach prioritizes versatility over pure capacity. The Transit ELWB maintains car-like driving dynamics while delivering commercial capability. Fleet managers report the flat floor and straight walls allow full-height shelving installations, eliminating wheel arch interference and maximizing storage system flexibility for trades.

A recent case study showed a plumbing firm fitted Transit ELWB with a three-tier shelving kit, reporting 22% faster daily job completion and fewer lost tools. Installation required just 2 hours, confirming the platform's conversion-friendly design.

Mercedes Sprinter ELWB: Premium Commercial Platform

The Mercedes-Benz Sprinter L3H3 extra-long panel van delivers 15.5m³ cargo volume with a 4,410mm load length and 1,787mm internal width, supported by maximum payload capacity of 2,479kg across its configurations. The standard loading height of 566mm facilitates easier equipment access and installation compared to many competing large van platforms.

Sprinter models extend cargo volume with reinforced chassis designs that accommodate heavier shelving installations while maintaining structural integrity. Ladder frame construction provides optimal mounting points for professional racking systems.

Mercedes Sprinter extra long models accommodate up to 55 linear meters of shelving with optimized weight distribution. The straight sidewall design prevents installation complications from wheel arch protrusions. Factory-fitted load securing rails simplify professional racking system integration and certification compliance.

Sprinter's Engineering Advantage

Sprinter's straight sidewalls and factory load securing rails remove many installation headaches and guarantee racking system integrity and compliance. This engineering advantage translates to faster installations and lower conversion costs for fleet operators.

In 2024, a UK maintenance fleet deployed 30 Sprinter models with multi-tier shelving. Storage capacity rose 38%, downtime fell 18%, attributed to improved organization. The combination of payload capacity and shelving compatibility makes Sprinter ELWB particularly suitable for tool-heavy trades.

Iveco Daily ELWB: Maximum Commercial Capacity

The Iveco Daily L3H2 extra-long model delivers 17.5m³ cargo volume, among the highest in its segment, with load length reaching 4,680mm and internal width of 1,800mm creating maximum shelving installation area. Payload capacity ranges from 1,220kg to over 4 tonnes depending on GVW specification, accommodating extensive racking systems without exceeding weight limits on 7-tonne configurations.

Iveco Daily models feature ladder frame chassis construction optimized for commercial conversions and shelving installations. Multiple wheelbase options from 4,350mm to 5,100mm allow precise capacity matching to specific storage requirements. The reinforced floor structure supports distributed loads up to 450kg/m².

Daily extra long models offer 25% more cargo volume than equivalent panel van configurations. The commercial vehicle design prioritizes durability and payload over passenger car-derived alternatives. Professional shelving systems integrate more effectively with the purpose-built chassis and body structure.

Daily's Commercial-First Design Philosophy

Iveco Daily's ladder-frame chassis and reinforced flooring are engineered specifically for heavy-duty van shelving and high-frequency load cycles. This commercial-first approach delivers superior mounting points and structural integrity compared to panel van conversions.

A national construction contractor retrofitted 14 Daily 72C21 ELWB vans for modular racking, achieving improved load consolidation and preventing costly overloading fines, with UK van penalties reaching a record £450,000 in 2025 due to improper load distribution. The combination of maximum payload and cubic capacity makes Daily ELWB ideal for material-intensive operations seeking both regulatory compliance and operational efficiency.

Other ELWB Contenders Worth Considering

VW Crafter ELWB: Refined Performance

The VW Crafter extra-long (Maxi) model delivers up to 18.4m³ cargo space with 4,855mm internal load length and 1,832mm width, offering first-class build quality and durable construction.

Payload ranges from 1,728kg to 2,027kg depending on engine and GVW specification. The refined driving dynamics and premium build quality appeal to operators requiring both capacity and professional road presence.

Renault Master ELWB: Value-Focused Option

Master ELWB models provide competitive 17m³ cargo volumes with French engineering focus on practicality and value.

Load compartment width of 1,870mm matches Sprinter dimensions for standardized shelving compatibility. Payload capacity reaches 1,625kg with the ELWB specification.

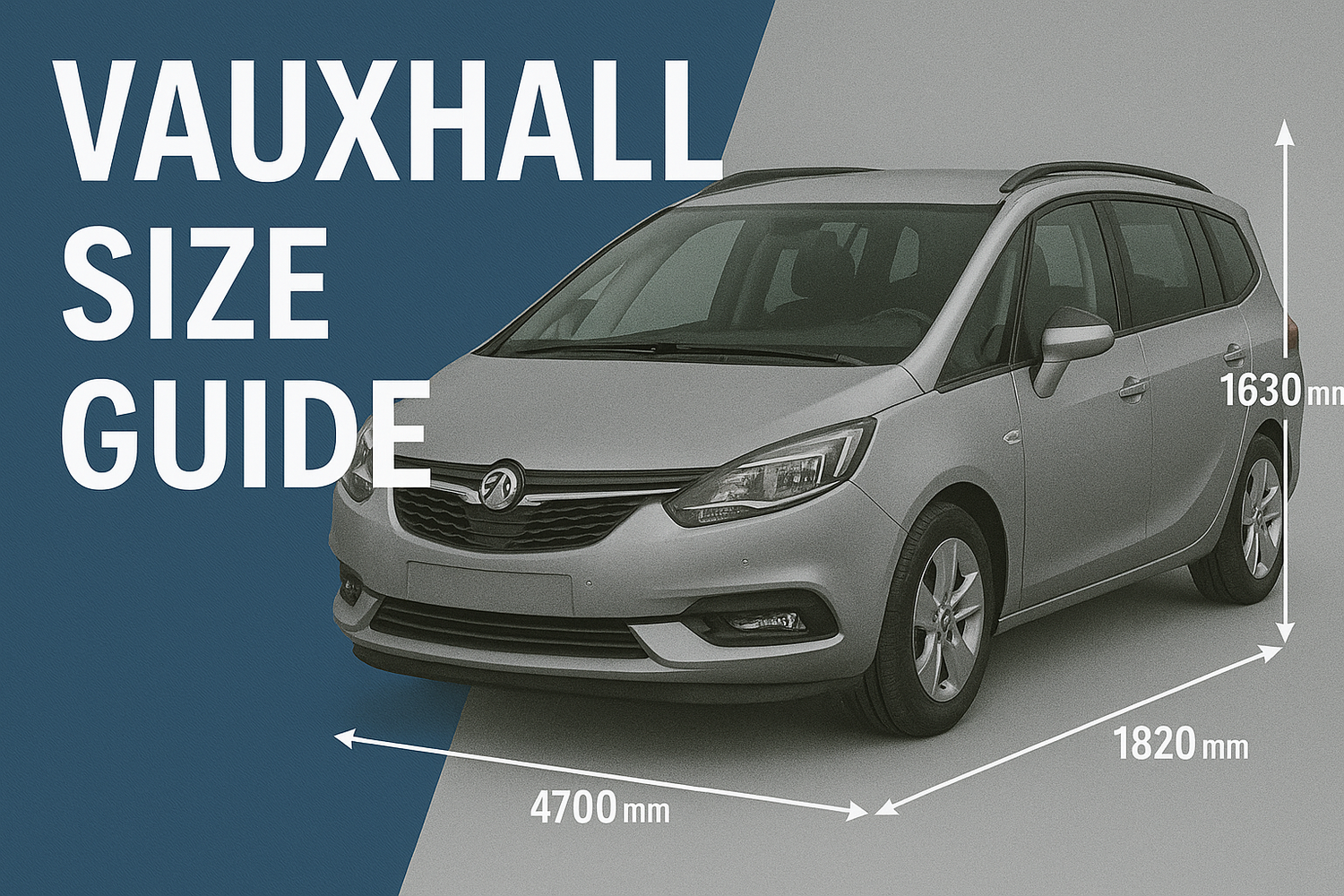

Fiat Ducato Maxi: Platform Sharing Benefits

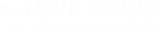

Ducato Maxi delivers up to 17m³ cargo volume sharing platform technology with Citroën Relay and Peugeot Boxer siblings.

The 4,035mm wheelbase provides good maneuverability while maintaining extended storage capacity. Competitive pricing positions Ducato as value-oriented shelving platform choice.

Professional Shelving Design Principles

Professional three-tier systems utilize full van height from floor to roof, creating 40-55 linear meters of storage in extra long configurations.

Shelf depths of 300-450mm optimize tool storage while maintaining central aisle access. Vertical dividers create compartmentalized storage preventing load shift during transit.

Critical Weight Distribution Guidelines

Optimal shelving layouts position heaviest items low and centered over or near the axles to maintain proper weight distribution and vehicle handling characteristics.

According to transport safety authorities, the load should be spread to keep the centre of gravity as low as possible, with larger and heavier items placed at the bottom to reduce rollover risk and maintain lateral stability during cornering and emergency maneuvers. Professional installations calculate weight per linear meter across mounting points to prevent exceeding axle limits, ensuring safe and compliant operations across all driving conditions.

Modular systems allow reconfiguration as business needs change without complete shelving replacement. Standardized components reduce replacement costs and allow expansion of existing installations. Professional modular designs maintain structural integrity while offering flexibility for different trade requirements.

Best Practices

Optimized shelving keeps the center of gravity low and positions bulk over the axles—critical for safe handling and compliance. Weight distribution affects braking distances, cornering stability, and tire wear patterns across the vehicle's service life.

In 2024, a UK builder installed modular shelving in a Sprinter ELWB, reducing van overloading fines to £0 and achieved 47% less wear on suspension, confirmed by maintenance logs. Proper installation protects both equipment and vehicle integrity.

UK Compliance Requirements for ELWB Operations

Professional shelving installations on vans require consideration of gross vehicle weight limitations and driving license requirements. Category B driving licences (standard car licenses passed after 1 January 1997) allow drivers to operate vans up to 3,500kg (3.5 tonnes) maximum authorised mass (MAM).

For vans exceeding 3.5 tonnes, a Category C1 licence is required, which permits vehicles between 3,500kg and 7,500kg. Proper documentation of van specifications, weight ratings, and shelving installation maintains compliance with DVLA regulations and insurance coverage.

London and major UK cities implement Ultra-Low Emission Zones (ULEZ) and Low Emission Zones (LEZ) affecting van operations. Euro 6 compliance becomes mandatory for diesel vans to operate without incurring daily charges in these zones—diesel vans registered before September 2016 are non-compliant and subject to daily ULEZ charges. Electric LCV (light goods vehicles) registrations are expanding rapidly, with zero-emission LGVs accounting for 8.2% of new registrations in Q1 2025, requiring lightweight shelving systems to preserve battery range and vehicle efficiency performance.

Professional shelving installations must meet crash safety standards to maintain comprehensive insurance coverage. Proper certification demonstrates compliance with health and safety regulations. Quality installations protect both cargo and occupants while reducing liability exposure for commercial operators.

Overloading Penalties and Prevention

Overloading fines are strictly graduated according to severity. Fixed penalties for overloading range from £100 for less than 10% overload, £200 for 10-15% overload, and £300 for 15% or more overload, with serious cases of 30%+ overloading resulting in court summons and fines up to £5,000 per overloaded axle. Shelving installations in ELWB vans must document payload and maintain compliance with DVSA regulations and insurance requirements to protect against liability and operational disruption.

A London-based courier revised fleet to include Euro 6 ELWB and modular lightweight racks. Emission zone access expanded 100%, with improved insurance acceptance. Compliance considerations affect route planning and operational flexibility.

Financial Analysis: ELWB vs Standard Wheelbase ROI

Extra long wheelbase vans typically cost £4,000-£7,000 more than equivalent standard wheelbase configurations before shelving installation, though pricing varies by model, specification, and market conditions.

Professional shelving systems add £1,500-£4,000 depending on complexity and materials. Total investment reaches £25,000-£35,000 for complete ELWB van with optimized storage systems.

Productivity and Efficiency Gains

ELWB vans with professional shelving reduce job completion times through improved organization and tool access. Additional capacity allows consolidated trips and reduced fuel costs per delivery. Professional appearance supports customer confidence and premium service pricing.

Quality shelving installations with proper weight distribution reduce maintenance costs, with balanced vans typically requiring 15-25% less in suspension-related repairs over their service life. Professional modular van shelving systems can be unbolted and transferred to another van the same day, allowing investment to extend beyond individual vehicle ownership periods.

Real-World ROI Examples

A regional utility fleet investing in professional shelving systems improved job completion efficiency and equipment organization, recognizing that shelving investments deliver significant ROI through reduced technician search time and increased job capacity per vehicle. Shelving was reused after vehicle decommissioning, extending useful life and return on investment across multiple fleet cycles.

Key ROI Factors:

- Time Savings: 15-25% faster job completion through better organization

- Fuel Efficiency: Consolidated trips reduce per-job fuel costs

- Professional Image: Better customer perception enables premium pricing

- Resale Protection: Quality shelving maintains interior condition

- Equipment Transfer: Modular systems move between vehicles

Making the Right ELWB Choice for Your Business

When selecting an ELWB van for maximum shelving capacity, consider these critical factors:

- Payload vs Volume Balance: Match vehicle capacity to your typical load requirements

- Shelving Material Weight: Aluminum saves 30-40% weight vs steel systems

- Installation Complexity: Factory load rails simplify professional installation

- Service Network: Choose brands with strong UK dealer support

- Compliance Requirements: Factor Euro 6 needs and urban access restrictions

Ready to transform your mobile workspace efficiency? Browse our complete range of custom van shelving solutions designed specifically for extra long wheelbase configurations.

Our modular systems install in under 2 hours and immediately boost your productivity. Contact VanShelves.co.uk today for expert guidance on the perfect shelving setup for your specific ELWB model and trade requirements.