Professional plumbers require specialized vehicle organization to deliver efficient service across residential and commercial locations in varying conditions. The service vehicle functions as both transportation and operational headquarters, necessitating thoughtful design that maximizes productivity while accommodating the unique requirements of plumbing materials and equipment.

Plumbing professionals rely on vehicle functionality for both emergency response calls and scheduled maintenance visits throughout their service territory. Effective van racking directly impacts service quality, completion time, and the professional impression conveyed to clients seeking reliable plumbing assistance during critical situations.

Selecting the Right Van for Plumbing Services

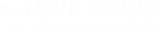

Van selection establishes the foundation for an effective mobile plumbing operation with appropriate capacity for pipes, tools, and fixtures. Mid-sized commercial vans like the Ford Transit, Mercedes Sprinter, or RAM ProMaster provide optimal balance between maneuverability and cargo capacity for comprehensive material and equipment storage.

The plumbing professional must evaluate cargo dimensions against anticipated inventory requirements, with special consideration for long pipe storage and heavy equipment transport. Dr. Michael Anderson of the Professional Trades Association notes, "The appropriate vehicle platform represents the most fundamental decision for service plumbers, directly impacting operational capabilities and future business growth potential."

Professional Van Racking Systems for Plumbers

Custom racking systems provide tailored solutions addressing the specific needs of plumbing professionals with precision-fitted components designed for pipe storage and tool organization. Modular systems offer flexibility for evolving business requirements and inventory adjustments as service offerings expand into specialized plumbing sectors.

Galvanized steel racking delivers superior durability for heavy plumbing tools while providing essential corrosion resistance in frequently damp conditions. Professional installation ensures proper anchoring to vehicle structure, preventing dangerous load shifting during emergency maneuvers or collision events while maximizing usable cargo space.

|

Racking Type |

Material |

Advantages |

Disadvantages |

Best For |

|

Fixed Steel Systems |

Galvanized steel |

Maximum durability, moisture resistance, highest strength |

Heaviest option, permanent installation |

Established businesses, heavy tools |

|

Modular Aluminum |

Aluminum alloy |

Lightweight, corrosion-resistant, reconfigurable |

Higher cost, lower maximum capacity |

Growing businesses, changing inventory |

|

Composite/Hybrid |

Multiple materials |

Customizable for specific needs, selective reinforcement |

Complex installation, higher initial cost |

Specialized plumbing services |

Pipe Storage and Organization Solutions

Effective pipe storage systems accommodate varying lengths, diameters, and materials while preventing damage during transport. Horizontal pipe racks with dividers prevent rolling and material contact damage between copper, PVC, PEX, and other tubing types commonly used in plumbing applications.

Vertical storage solutions maximize floor space utilization through ceiling-mounted or wall-mounted tube holders with secure retention systems. Research by the Plumbing Contractors Association found that optimized pipe storage can reduce material waste by up to 23% while improving job site readiness for immediate installation.

The most effective pipe organization systems incorporate:

-

Horizontal racks with divided sections for different pipe types

-

Vertical tube storage for maximum space efficiency

-

Length indicators for quick inventory assessment

-

Front and rear access points for FIFO (first in, first out) rotation

-

Protective sleeves preventing scratches on finished materials

-

Retention systems preventing movement during transit

-

Modular design accommodating varying project requirements

Essential Tool Organization for Plumbing Professionals

Effective tool organization requires strategic categorization based on frequency of use and related plumbing repair functions. Primary access zones should contain frequently used items like pipe wrenches, cutters, and basic hand tools positioned at ergonomic heights for quick retrieval.

Plumbing professionals benefit from visual organization systems implementing color-coding or labeling for rapid identification during time-sensitive repair scenarios. A comprehensive study by the National Association of Plumbing Contractors found that systematically organized service vehicles reduce repair time by up to 32% compared to poorly organized alternatives.

Tool organization should follow these core principles:

-

Position high-frequency tools at waist height for ergonomic access

-

Store heavy equipment low and centered for vehicle stability

-

Group related tools together by function or repair type

-

Implement foam tool shadowing for immediate identification of missing items

-

Create dedicated zones for frequently used tool combinations

-

Separate clean tools from those used in drain cleaning operations

Parts Inventory Management in Your Service Vehicle

Parts inventory organization enables quick retrieval of appropriate components for various plumbing scenarios without return trips to suppliers. Transparent bins with clear labeling facilitate visual identification of fittings, valves, and common replacement parts across different materials and sizes.

Systematic arrangement prevents inventory obsolescence while streamlining restocking procedures after service calls. Plumbing professionals benefit from inventory tracking systems maintaining appropriate stock levels of frequently used components for common service needs across residential and commercial applications.

|

Part Category |

Storage Solution |

Identification Method |

Inventory Control |

|

Copper Fittings |

Divided bins with size separation |

Color-coded size labeling |

Min/max card system |

|

PVC/ABS Fittings |

Stackable containers |

Size/type visual organization |

Barcode inventory |

|

Specialty Valves |

Padded individual compartments |

Numbered reference system |

Digital tracking |

|

Fasteners/Hardware |

Multi-drawer organizers |

Size/material classification |

Weight-based monitoring |

|

Washers/O-rings |

Transparent divided containers |

Size calibration charts |

Visual verification |

Creating a Functional Mobile Workbench

Mobile workbench solutions transform the service vehicle into a productive repair environment through stable work surfaces at ergonomic heights. Fold-down or slide-out workbenches maximize available space while providing sturdy platforms for precision plumbing work including threading, cutting, and assembly operations.

Integrated pipe vises, cutting stations, and assembly areas create comprehensive workstations supporting diverse repair requirements encountered during service calls. Professor Jennifer Williams' research in field service efficiency concluded, "Purpose-built mobile workstations can reduce repair preparation time by up to 47% while improving quality control during complex plumbing operations."

Water Leak Detection Equipment Organization

Leak detection equipment represents significant financial investment requiring protection from physical damage and environmental factors. Padded compartments with custom foam inserts prevent movement damage to sensitive electronic components including acoustic sensors, thermal imagers, and moisture meters.

Proper positioning ensures quick deployment for efficient troubleshooting procedures at service locations. Dedicated charging stations maintain battery readiness for electronic diagnostic tools through integrated power management systems accessible while driving between service locations.

Drain Cleaning Equipment Storage Solutions

Specialized storage solutions for drain cleaning equipment prevent cross-contamination while containing potential moisture and debris. Sealed compartments with washable liners isolate used drain snakes, augers, and jetters from clean tools and materials carried in the same vehicle.

Ventilated storage areas prevent odor development and moisture accumulation damaging equipment over time. Dr. Robert Thompson of Plumbing Technology Institute states, "Proper containment of drain cleaning equipment represents both a professional necessity and a health consideration for service technicians spending extended time in their vehicles."

Fixture Transport and Protection Systems

Fixture transport systems prevent damage to toilets, sinks, water heaters, and other fragile plumbing components during delivery to job sites. Padded dividers, adjustable straps, and custom cradles secure irregular shapes preventing movement during transit while protecting finished surfaces.

Strategic placement ensures proper weight distribution while maintaining accessibility for site delivery. Protection systems reduce replacement costs due to transit damage while conveying professional care in all aspects of service delivery to observant clients.

Power Tool Storage and Accessibility

Power tools require specialized storage considerations protecting sensitive components from impact damage and environmental exposure in the challenging conditions of plumbing work. Protective cases with moisture-resistant features prevent water damage to electronic components frequently encountered in plumbing operations.

Dedicated charging stations maintain battery readiness for cordless tools through integrated power management systems. Drainage industry expert Dr. Elizabeth Martinez explains, "The most significant productivity advances in recent years stem from cordless tool technologies, making proper charging infrastructure a critical element of vehicle organization."

Optimal power tool organization includes:

-

Dedicated impact-resistant cases for each major tool

-

Centralized battery charging station

-

Moisture protection features

-

Quick-access positioning for frequently used items

-

Inventory tracking system for job site accountability

-

Secondary retention systems preventing case movement

-

Integration with workbench for operational efficiency

Weight Distribution and Vehicle Performance

Strategic weight distribution ensures vehicle stability and safe handling characteristics during both emergency response and normal operation between service locations. Heavy equipment positioned low and centrally improves vehicle dynamics and reduces wear on suspension components and tires during extensive service routes.

Balanced loading improves fuel efficiency and reduces operational costs for plumbing service providers. The Commercial Vehicle Safety Alliance reports that "properly distributed cargo can improve vehicle handling response by up to 22% while significantly enhancing braking performance during emergency situations commonly encountered in service operations."

Professional Branding for Your Plumbing Van

Vehicle branding transforms service vans into mobile marketing platforms generating continuous visibility throughout the service area. Professional graphics communicate plumbing expertise and emergency service availability to potential clients encountering the vehicle during daily operations.

Clear contact information with service specializations facilitates immediate inquiry from prospects requiring plumbing assistance. The Service Marketing Institute found that well-designed service vehicle graphics generate between 30,000-70,000 visual impressions daily in urban environments, creating substantial marketing value beyond transportation utility.

Budget-Friendly Van Racking Ideas for New Plumbers

New plumbing businesses can implement cost-effective storage solutions while building service revenue for future upgrades to professional systems. Modified retail storage solutions provide organized accessibility without the investment in plumbing-specific systems during the startup phase.

Modular component systems allow incremental upgrades as business growth justifies additional investment in specialized storage. Emerging plumbing professionals should prioritize basic organization while planning for future upgrades aligned with business specialization and service territory.

Economical organization strategies include:

-

PVC pipe storage systems created from plumbing materials

-

Repurposed retail shelving with added restraint systems

-

Overhead storage utilizing ceiling space for pipe storage

-

DIY drawer systems using furniture slides with locking mechanisms

-

Pegboard or slat wall systems for vertical organization

-

Magnetic tool strips for metal surfaces

-

Modified plastic bins with secured mounting points

Advanced Van Customization for Established Plumbing Businesses

Established plumbing operations benefit from comprehensive vehicle customization addressing specific business specializations in residential, commercial, or industrial sectors. Integrated testing systems with dedicated water supplies create efficient troubleshooting stations within the mobile environment.

Specialized equipment mounts for inspection cameras, hydrojetting equipment, or electronic diagnostic tools enhance service capabilities at customer locations. Industry consultant Dr. Michael Roberts notes, "Advanced vehicle customization represents the operational difference between basic service providers and comprehensive plumbing solution specialists commanding premium service rates."

Maintenance and Organization Systems

Regular maintenance prevents premature deterioration of racking components and storage systems under the challenging conditions of plumbing service work. Scheduled inspections should evaluate mounting security, drawer functionality, and structural integrity of all installed systems subject to heavy loads and frequent use.

Cleaning protocols maintain professional appearance while preventing cross-contamination between service locations. Well-maintained organizational systems project professionalism while extending equipment lifespan and protecting substantial tool investments necessary for comprehensive plumbing services.

Conclusion: Transforming Your Service Vehicle into a Professional Mobile Plumbing Workshop

Effective van racking transforms standard vehicles into professional mobile workshops supporting comprehensive plumbing service operations across diverse environments. Strategic organization directly impacts service quality, efficiency, and business profitability through improved tool access and inventory management during critical client interactions.

Professional plumbers benefit from continuous improvement of their vehicle systems addressing evolving service requirements and technological advancements. The optimized service vehicle serves as both functional workspace and business ambassador, reflecting the plumber's commitment to professional excellence and responsive customer service during every client interaction.

Frequently Asked Questions

What is the most important factor when designing a plumber's van layout? Workflow efficiency based on service specialization and frequency of tool use determines optimal layout for plumbing service operations in residential and commercial applications.

How should copper and PEX pipes be stored to prevent damage? Copper requires padded dividers preventing contact with other materials, while PEX benefits from curved supports maintaining natural coil shape without kinking or deformation.

What's the best way to organize different sizes of pipe fittings? Transparent divided containers with clear size labeling arranged in sequential order provide optimal organization while preventing mixing between materials requiring different installation techniques.

How can plumbers effectively store drain cleaning equipment to prevent contamination? Sealed compartments with washable liners, ventilation features, and physical separation from clean tools prevent cross-contamination and odor development.

What's the ideal height for a mobile workbench in a plumber's van? Ergonomic workbench height positions work surface 2-4 inches below elbow height when standing, typically 38-42 inches for average technicians performing precision plumbing work.

How should electronic leak detection equipment be protected in a service vehicle? Electronic tools require cushioned storage with moisture protection, temperature control features, and secure mounting away from potentially wet areas of the vehicle.

What weight distribution principles matter most for plumbing service vehicles? Heavy items positioned low and centered between axles improves stability, with pipe storage arranged longitudinally to prevent uneven side-loading affecting handling characteristics.

What are the most essential tools to keep in the most accessible locations? Emergency shut-off tools, basic hand wrenches, leak detection equipment, and initial diagnostic tools require immediate accessibility in primary access zones nearest vehicle doors.

How can plumbers manage inventory of small parts like washers and o-rings? Transparent divided organizers with size indicators and minimum quantity markers facilitate visual inventory management of small components frequently needed during service calls.

What's the best lighting system for a plumber's service van? LED lighting systems with color temperatures between 4000-5000K provide accurate color rendering for pipe identification while minimizing power consumption during extended operation.

How should water heaters and large fixtures be secured during transport? Adjustable strapping systems with padded contact points and dedicated floor-mounted D-rings prevent movement while distributing restraint forces across non-functional surfaces.

What considerations matter when storing battery-powered plumbing tools? Battery tools need dedicated charging stations, moisture protection, temperature control, and physical retention systems preventing tool damage during vehicle movement.

How can new plumbers create economical pipe storage solutions? PVC storage systems constructed from plumbing materials with end caps and secure mounting provide cost-effective organization compared to commercial alternatives during business startup.

What's the biggest mistake plumbers make when organizing their service vans? Inadequate planning for wet/dry separation creates potential for contamination and damage to sensitive equipment, significantly reducing service life of expensive tools.

How often should plumbing van organization systems be evaluated and updated? Quarterly assessments identify improvement opportunities while major reorganization typically occurs every 2-3 years based on changing service patterns and equipment acquisition.