Key Takeaways

-

Proper ergonomics in van racking reduces physical strain, prevents injuries, and increases productivity

-

The Golden Zone principle places frequently used items between shoulder and knee height for optimal access

-

Strategic organization based on frequency of use can save up to 30% of your working time

-

Weight distribution is crucial for both vehicle handling and preventing lifting injuries

-

Customized solutions based on trade-specific needs deliver the best ergonomic benefits

Explore our complete van racking collections at Van Racking

Introduction to Van Ergonomics

The van is more than just a vehicle for many professionals—it's a mobile workshop, office, and storage facility rolled into one. Whether you're an electrician, plumber, carpenter, or delivery professional, how you organize this space can make the difference between an efficient workday and one filled with frustration and physical strain.

Ergonomics—the science of designing workspaces to fit the people who use them—is often overlooked in van setup. Yet, implementing ergonomic principles in your van racking layout is perhaps one of the most impactful investments you can make for your business and wellbeing.

Poor ergonomic design in your mobile workspace doesn't just slow you down; it can lead to serious health issues over time. Repetitive strain injuries, back problems, and muscle fatigue are common among tradespeople who repeatedly reach, bend, and lift in poorly designed spaces. In fact, work-related musculoskeletal disorders account for approximately 30% of all workplace injuries, with many of these preventable through proper ergonomic design.

Let's explore how to transform your van into an ergonomic powerhouse that protects your health while boosting your productivity.

The Fundamentals of Ergonomic Van Racking Design

Understanding Movement Patterns and Workflow

Before installing a single shelf or drawer, take time to analyze your typical workday. What tools and materials do you use most frequently? What is your sequence of tasks? How do you move in and around your van?

This workflow analysis reveals patterns that should inform your racking layout. For instance, items used together should be stored together, and your most commonly accessed equipment should be placed in easily accessible locations.

Consider keeping a work diary for a week, noting which items you access most frequently and at what points in your day. This simple exercise can reveal inefficiencies you might not have noticed and provide a foundation for your ergonomic design.

The Rule of Reach: Organizing by Access Frequency

One of the most fundamental ergonomic principles is organizing your van's contents by how often you use them:

Primary Zone (High-Frequency Items)

-

Located between waist and shoulder height

-

Within arm's reach without bending or stretching

-

Should contain tools and materials used multiple times daily

-

Examples: hand tools, testing equipment, fasteners

Secondary Zone (Moderate-Frequency Items)

-

Located between knee and shoulder height

-

May require some bending or reaching, but still relatively accessible

-

For items used several times a week

-

Examples: power tools, medium-sized materials, specialized equipment

Storage Zone (Low-Frequency Items)

-

Located in higher or lower positions, or deeper in storage systems

-

For items used occasionally or seasonally

-

May require more effort to access but doesn't impact daily efficiency

-

Examples: rarely used specialized tools, bulk supplies, seasonal equipment

By following this organizational approach, you can reduce unnecessary movements and save valuable time—professionals report saving up to 30% of their working time with properly organized vehicles.

Weight Distribution and Lifting Considerations

Proper weight distribution serves two crucial purposes in your van: it ensures safer vehicle handling and prevents lifting injuries.

For Vehicle Safety:

-

Place heaviest items low and centered over the axles

-

Distribute weight evenly from side to side

-

Secure all items to prevent shifting during transit

-

Stay within your vehicle's payload capacity

For Ergonomic Lifting:

-

Store heavy items between knee and waist height

-

Use slide-out systems for easier access to heavy equipment

-

Install lifting aids for items exceeding safe manual handling weights

-

Avoid storing heavy items overhead or in positions requiring awkward postures

Remember the ergonomic rule: the farther an item is from your body when lifting, the more strain it places on your back. A 10kg object held at arm's length puts nearly 100kg of force on your lower back!

Key Ergonomic Principles for Van Racking Layout

The "Golden Zone" Principle

The "Golden Zone" represents the optimal area for accessing frequently used items—typically between shoulder and knee height, where you can comfortably reach without straining. This zone minimizes bending, stretching, and awkward postures that lead to fatigue and injury.

To maximize your Golden Zone:

-

Position your most frequently used items within this area

-

Consider your height and adjust accordingly (taller individuals may have a higher Golden Zone)

-

Use pull-out drawers and sliding systems to bring items from deeper storage into this zone

-

Install adjustable shelving that can be reconfigured as your needs change

Studies show that working within this optimal zone can reduce physical strain by up to 40% compared to constantly reaching above shoulder height or below knee level.

Minimizing Repetitive Strain

Repetitive movements are a leading cause of work-related injuries for tradespeople. Your van racking system can help minimize these risks:

-

Group related tools and materials to reduce unnecessary movements

-

Install drawer slides and door mechanisms that open and close with minimal effort

-

Consider ergonomic handle designs that accommodate a natural grip

-

Use dividers and organizers to keep small items visible and accessible without rummaging

-

Install anti-vibration mats under frequently used equipment to reduce impact stress

Remember that ergonomics isn't just about avoiding injury—it's about working smarter. A well-designed system reduces fatigue, allowing you to maintain energy throughout your workday.

Clear Pathways and Access Points

Even the most ergonomically arranged items become problematic if you can't easily access them. Consider your movement patterns:

-

Ensure doorways and pathways remain clear of obstructions

-

Allow sufficient clearance for safe entry and exit

-

Consider whether side and rear door access points are both optimized

-

Choose sliding systems over hinged doors where space is limited

-

Design for weather protection at access points to keep you (and your equipment) dry during loading/unloading

Your van's layout should accommodate not just storage, but the dynamic process of retrieving and returning items throughout your workday.

Ergonomic Van Racking Solutions for Different Trades

Electricians and Cable Management

Electricians face unique challenges with numerous small components, delicate testing equipment, and cable management.

Ergonomic Solutions for Electricians:

-

Transparent small parts organizers positioned at eye level

-

Cable reel holders that allow dispensing without removal

-

Test equipment stored in padded drawers at mid-height

-

Vertical storage for conduit and longer materials

-

Charging stations for battery-powered tools within the Golden Zone

Many electricians find that a combination of open shelving for frequently accessed items and closed storage for valuable testing equipment provides the ideal balance.

Plumbers and Pipework Storage

Plumbers contend with long materials, heavy tools, and often wet working conditions.

Ergonomic Solutions for Plumbers:

-

Pipe tube storage accessible from outside the van

-

Heavy tools positioned at waist height to reduce lifting strain

-

Waterproof compartments for wet tools and equipment

-

Drawer systems for organized fitting storage within the Golden Zone

-

Secure storage for fragile items like porcelain fixtures

A well-organized plumbing van typically features a combination of long material storage, heavy-duty drawers, and specialized compartments for unique tools.

Carpenters and Woodworkers

Carpenters manage an array of power tools, sheet materials, and often dusty conditions.

Ergonomic Solutions for Carpenters:

-

Power tool storage with integrated charging within the Golden Zone

-

Sheet material racks designed for easy loading/unloading

-

Dust extraction systems integrated into the storage design

-

Secured storage for precision tools to prevent damage

-

Adjustable compartments for materials of varying dimensions

Carpenters often benefit from modular systems that can be reconfigured as project requirements change throughout the year.

Customization vs. Standardization in Ergonomic Van Racking

While standardized racking systems offer convenience and predictability, customized solutions can address your specific ergonomic needs. The ideal approach often combines elements of both:

Benefits of Customized Solutions:

-

Tailored to your specific workflow and physical requirements

-

Addresses unique storage needs for specialized equipment

-

Can be adapted to your vehicle's exact dimensions

-

May provide better ergonomic benefits for your specific trade

Advantages of Standardized Systems:

-

Often more cost-effective

-

Easier to transfer to new vehicles

-

Proven designs based on extensive testing

-

Typically faster to install

Many professionals find that semi-customized solutions—standardized components arranged in customized configurations—offer the best of both worlds.

Implementing Ergonomic Principles: A Step-by-Step Approach

-

Analyze Your Workflow

-

Track which tools and materials you use most frequently

-

Note when and how you access your van throughout the day

-

Identify pain points in your current system

-

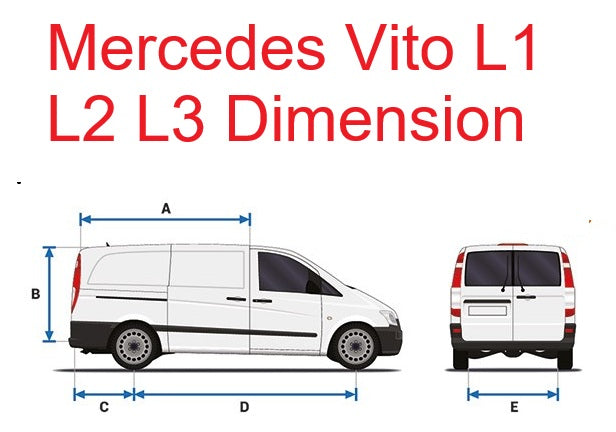

Measure and Map Your Van Interior

-

Create a detailed floor plan including dimensions

-

Note structural elements that might impact racking placement

-

Consider door openings and access points

-

Design Your Layout

-

Apply the Golden Zone principle for frequently used items

-

Position items according to frequency of use

-

Consider weight distribution for vehicle handling

-

Test Before Permanent Installation

-

Use temporary shelving or mockups to test your design

-

Work from this setup for several days if possible

-

Note any inefficiencies or awkward movements

-

Install Your Racking System

-

Choose quality components that will withstand daily use

-

Ensure all systems are securely attached to the vehicle

-

Double-check weight distribution once loaded

-

Evaluate and Adjust

-

After using your new system for a month, assess its effectiveness

-

Make adjustments based on real-world usage patterns

-

Consider seasonal variations in your equipment needs

This methodical approach ensures your ergonomic van racking system truly serves your specific needs rather than forcing you to adapt to an ill-fitting system.

Additional Ergonomic Considerations

Lighting and Visibility

Poor lighting leads to eye strain, missed details, and safety hazards:

-

Install LED lighting throughout your van interior

-

Position task lighting over workbenches or preparation areas

-

Use light-colored surfaces to maximize brightness

-

Consider motion-activated lighting for convenience

-

Implement color-coding systems for quick identification of items

Proper lighting reduces the time spent searching for items and decreases the likelihood of errors, particularly during early morning or evening work.

Climate Control and Comfort

Temperature extremes can affect both your comfort and the condition of your tools and materials:

-

Consider insulation for temperature-sensitive equipment

-

Install ventilation systems to reduce humidity and condensation

-

Use weather guards at entry points to minimize exposure during loading/unloading

-

Store temperature-sensitive materials and chemicals appropriately

-

Consider your own comfort during periods of loading/unloading

Climate considerations are particularly important for professionals working with materials affected by temperature and humidity, such as adhesives, paints, and electronics.

Future-Proofing Your Ergonomic Layout

Your needs will evolve over time, and your van racking system should accommodate these changes:

-

Choose modular systems that can be reconfigured

-

Allow some flexible space for new equipment

-

Select systems that can transfer to new vehicles when necessary

-

Consider technological changes in your industry when planning

-

Build in adaptability for seasonal variations in equipment needs

An investment in flexible, ergonomic van racking pays dividends throughout your career by protecting your health and enhancing your productivity.

FAQ: Ergonomic Van Racking

Q: How much should I budget for an ergonomic van racking system?

A: Professional ergonomic racking systems typically range from £800 for basic setups to £3,000+ for comprehensive custom solutions. While this represents a significant investment, the returns in efficiency, reduced injury risk, and professional presentation make it worthwhile for most trades. Many professionals report recouping costs through increased productivity within 6-12 months.

Q: Can I install an ergonomic racking system myself?

A: While DIY installation is possible for those with appropriate skills, professional installation ensures safety, proper weight distribution, and optimal ergonomic positioning. If you choose to self-install, always follow manufacturer guidelines and check vehicle-specific weight limitations.

Q: How do I know if my current van layout is causing ergonomic problems?

A: Warning signs include back pain after workdays, fatigue, frequently dropping items, difficulty finding tools, and spending excessive time retrieving equipment. If you find yourself avoiding certain tasks due to the effort of accessing materials, your layout likely needs ergonomic improvement.

Q: Will an ergonomic system work if multiple people use the same van?

A: Yes, but with careful planning. Design for the average height of users, ensure adjustability where possible, and prioritize the Golden Zone principle even more strictly. Clear labeling and consistent organization become especially important with multiple users.

Q: How often should I reassess my van's ergonomic layout?

A: Conduct a thorough review annually, with minor adjustments as needed throughout the year. Additionally, reassess whenever you add new services, change major equipment, or notice inefficiencies developing in your workflow.

Conclusion: Investing in Ergonomic Van Racking

Implementing ergonomic principles in your van racking layout is an investment in both your business efficiency and your long-term health. The mobile professional who prioritizes ergonomics enjoys numerous benefits:

-

Reduced risk of work-related injuries and associated downtime

-

Increased daily productivity through efficient organization

-

Enhanced professional image when arriving at client sites

-

Lower stress levels from working in an organized environment

-

Extended career longevity through reduced physical strain

Your van is more than transportation—it's the foundation of your mobile business. By applying ergonomic principles to its organization, you transform it from a simple cargo carrier into a strategic business asset that supports your success every day.

Ready to optimize your mobile workspace with ergonomic van racking solutions? Explore our complete range of customizable systems at vanshelves and discover how the right setup can revolutionize your workday.