Key Takeaways

-

Plywood offers the best balance of strength, weight, and cost for most van racking applications

-

Material thickness between 12-18mm provides optimal durability without excessive weight

-

Wood treatment is essential for extending the lifespan of your van racking system

-

Birch plywood delivers premium quality for professional installations requiring maximum durability

-

Weight considerations are crucial - heavier wood reduces fuel efficiency and payload capacity

View our complete van racking collection at vanshelves

Introduction

The foundation of any reliable van racking system starts with one critical decision: choosing the right wood. Whether you're a tradesperson looking to organize tools, a delivery driver maximizing cargo space, or a van conversion enthusiast building your dream setup, the type of wood you select will impact everything from durability and weight to cost and functionality.

With numerous options available in today's market, making an informed choice can seem overwhelming. This comprehensive guide will walk you through everything you need to know about selecting the perfect wood for your van racking system, helping you balance practical considerations with performance requirements.

By the end of this article, you'll have the knowledge to confidently choose materials that meet your specific needs, ensuring your van racking solution stands the test of time while maximizing efficiency and organization. Let's dive into the world of van racking wood options and discover which material will best support your professional or personal requirements.

Why Wood Choice Matters for Van Racking

Weight Considerations

The weight of your van racking directly impacts your vehicle's fuel efficiency and available payload capacity. Every kilogram of wood added to your van means one less kilogram of tools, equipment, or products you can legally carry. Heavier woods like solid timber significantly increase fuel consumption over time, while lightweight alternatives like honeycomb boards might sacrifice durability.

Most commercial vans have weight restrictions ranging from 2.8 to 3.5 tonnes Gross Vehicle Weight (GVW). Professional installations typically aim to keep racking weight below 10% of the vehicle's payload capacity, leaving maximum space for the cargo that generates your income.

Durability Factors

Van interiors face harsh conditions – from vibration and impact during driving to moisture variations and temperature fluctuations. Your chosen wood must withstand:

-

Daily loading and unloading of heavy equipment

-

Accidental impacts from shifting cargo

-

Exposure to water, oils, and other liquids

-

Temperature changes that cause expansion and contraction

Woods with high tensile strength and good impact resistance, like birch plywood, maintain structural integrity even after years of commercial use. In contrast, particleboard may deteriorate rapidly under similar conditions, creating safety hazards and requiring frequent replacement.

Cost Implications

Material costs vary dramatically across wood types. While premium options like furniture-grade birch plywood might cost 3-4 times more than basic OSB (Oriented Strand Board), they typically offer proportional increases in lifespan and performance.

Consider the total cost of ownership rather than just initial investment. A higher-quality wood that lasts 7-10 years ultimately proves more economical than cheaper alternatives requiring replacement every 2-3 years – not to mention the downtime and reinstallation costs associated with premature system failure.

Environmental Impact

Sustainability considerations are increasingly important for businesses and individuals alike. Look for woods with FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) certification, ensuring materials come from responsibly managed forests.

Additionally, certain wood treatments contain VOCs (Volatile Organic Compounds) that can off-gas into your van's enclosed space. Water-based treatments offer environmentally friendly alternatives without compromising protection.

Types of Wood for Van Racking

Plywood

Properties: Plywood consists of multiple thin wood layers (plies) bonded together with the grain direction alternating between layers. This cross-laminated structure distributes stress evenly, creating exceptional strength-to-weight characteristics.

Advantages:

-

Excellent strength-to-weight ratio

-

Resists warping and splitting

-

Available in various grades and thicknesses

-

Good screw retention properties

-

Relatively affordable compared to premium options

Disadvantages:

-

Quality varies significantly between grades

-

Lower grades may contain voids or weak spots

-

Requires edge sealing to prevent moisture ingress

-

Heavier than some engineered alternatives

Best Applications: Standard plywood (12-18mm thickness) performs exceptionally well for general van racking, shelving, and drawer systems. It's particularly suitable for tradespeople who need to balance durability with weight constraints.

MDF (Medium-Density Fiberboard)

Properties: MDF is manufactured by breaking down hardwood or softwood residuals into wood fibers, combining them with wax and resin binder, and forming panels under high temperature and pressure.

Advantages:

-

Smooth, consistent surface ideal for painting

-

No grain pattern means no splitting

-

Excellent dimensional stability

-

Cost-effective option

-

Easy to machine and cut precisely

Disadvantages:

-

Significantly heavier than plywood

-

Poor moisture resistance unless specially treated

-

Limited screw-holding ability, especially at edges

-

Less impact-resistant than plywood

-

Tends to sag under sustained loads

Best Applications: MDF works well for non-structural components in van racking, such as cabinet doors, decorative panels, or internal dividers. It's less suitable for load-bearing shelves or components exposed to moisture.

Birch Plywood

Properties: A premium plywood variant made exclusively from birch veneers, offering superior strength, consistency, and aesthetic qualities.

Advantages:

-

Exceptional strength and durability

-

Minimal voids and consistent quality throughout

-

Superior screw retention

-

Attractive natural finish

-

Excellent resistance to vibration

-

Outstanding dimensional stability

Disadvantages:

-

Significantly more expensive than standard plywood

-

Heavier than some alternatives

-

May be overspecified for basic applications

Best Applications: Birch plywood represents the gold standard for professional van fit-outs, particularly for heavy-duty applications or when presentation matters. It's ideal for custom installations in service vehicles where reliability is paramount, such as mobile workshops or specialized trade vans.

Other Wood Options

Oriented Strand Board (OSB)

OSB consists of compressed wood strands arranged in cross-oriented layers. While more affordable than plywood, it's generally heavier, less moisture-resistant, and provides inferior screw retention. It remains viable for budget installations with limited load requirements.

Lightweight Honeycomb Boards

These innovative panels feature a honeycomb core sandwiched between thin wood or composite faces. While extraordinarily lightweight, they typically lack the durability needed for commercial applications and remain better suited to recreational van conversions with minimal load requirements.

Bamboo Plywood

An eco-friendly alternative gaining popularity, bamboo plywood offers impressive strength-to-weight characteristics and natural antimicrobial properties. However, its higher cost and limited availability make it less common in commercial van racking applications.

Factors to Consider When Choosing Wood for Van Racking

Van Type and Size

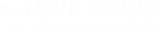

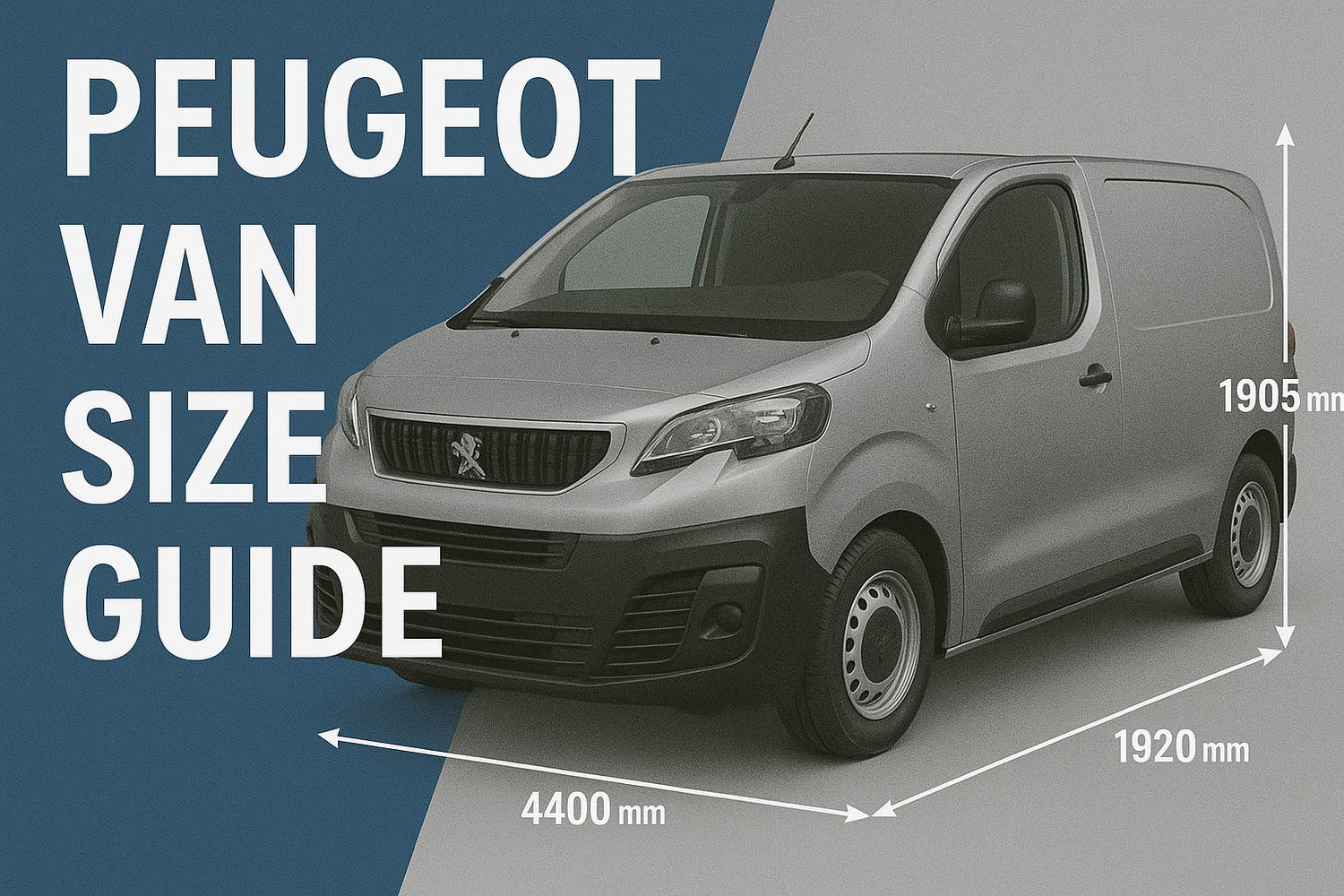

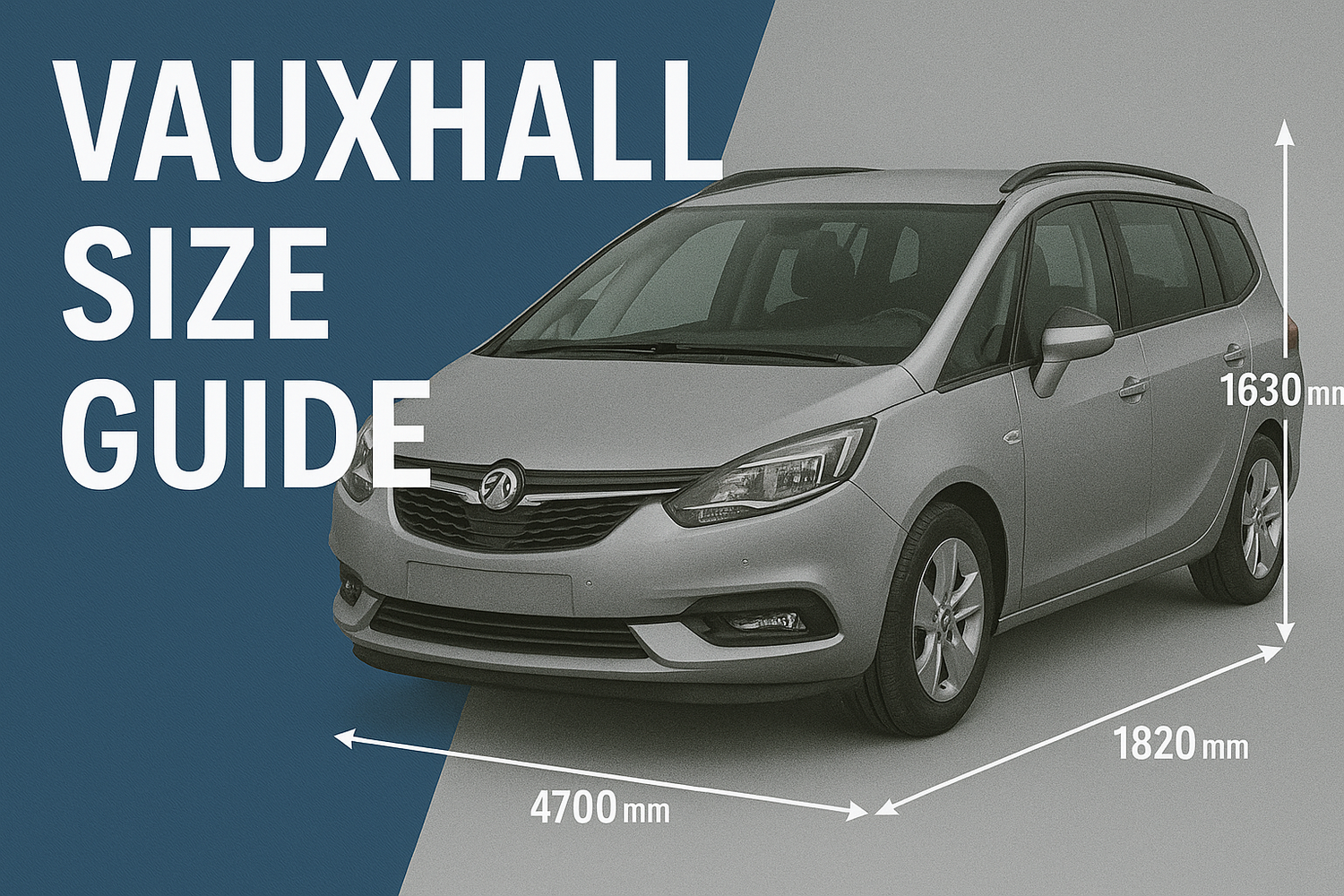

Different van models present unique considerations:

-

Small vans (like Volkswagen Caddy or Ford Transit Connect) benefit from lightweight materials to maintain payload capacity

-

Medium vans (Ford Transit Custom, Volkswagen Transporter) can accommodate standard 12-15mm plywood for most applications

-

Large vans (Mercedes Sprinter, Ford Transit) may require thicker materials (15-18mm) for longer unsupported spans

Consider your van's interior dimensions when planning racking depth. Standard plywood sheets (2440mm × 1220mm) may require cutting to maximize material efficiency based on your specific vehicle.

Type of Work/Industry

Your professional requirements should guide material selection:

-

Plumbers/electricians: Moisture-resistant plywood for carrying potentially wet tools

-

Carpenters/joiners: Birch plywood that can withstand heavy tool storage

-

Delivery services: Lightweight options to maximize payload capacity

-

Mobile mechanics: Heavy-duty materials that resist oil contamination

-

Florists/caterers: Food-safe finishes for transporting consumable products

Load Requirements

Accurately assess the weight your racking must support:

-

Light loads (under 20kg per shelf): 12mm standard plywood

-

Medium loads (20-40kg per shelf): 15mm plywood or 12mm birch plywood

-

Heavy loads (40kg+ per shelf): 18mm plywood or 15mm birch plywood

For exceptionally heavy items, consider reinforcing high-stress areas with metal brackets or additional support structures.

Budget Constraints

Balance initial investment against long-term value:

-

Economy option: OSB with protective coating (2-4 year lifespan)

-

Standard option: Marine-grade plywood (5-7 year lifespan)

-

Premium option: Birch plywood with professional finish (8-10+ year lifespan)

Remember that labor costs for installation often exceed material costs, making durability a wise investment even with budget limitations.

Installation Method

Your installation approach affects material requirements:

-

DIY installations benefit from easier-to-work materials like standard plywood

-

Modular systems typically specify compatible materials in their instructions

-

Professional installations often utilize precision-cut birch plywood

-

Temporary setups might justify more economical materials

Weather and Environmental Exposure

Consider your typical operating conditions:

-

Vehicles frequently operated in high-humidity environments require moisture-resistant treatments

-

Extreme temperature variations necessitate woods with superior dimensional stability

-

Off-road applications benefit from materials that resist vibration and impact

Wood Treatments and Finishing

Water-Resistant Treatments

Moisture represents one of the greatest threats to wooden van racking. Consider these protective options:

-

Marine-grade plywood contains waterproof adhesives between plies

-

Wood sealants like polyurethane create a protective barrier

-

Edge sealing prevents moisture ingress at exposed cut edges

-

Water-repellent additives can be incorporated during manufacturing

Even with treatment, avoid direct and prolonged water exposure to maximize longevity.

Fire-Retardant Options

Safety considerations may necessitate fire-resistant properties, particularly for commercial vehicles. Fire-retardant treatments:

-

Comply with specific industry regulations

-

Reduce flame spread rates

-

Self-extinguish when ignition source is removed

-

May be required for commercial insurance policies

These treatments typically add 15-25% to material costs but provide valuable safety benefits.

Protective Coatings and Finishes

The right finish enhances both functionality and appearance:

-

Polyurethane varnish: Creates a hard-wearing, moisture-resistant surface

-

Oil-based finishes: Penetrate wood fibers for excellent protection

-

Laminate coverings: Provide superior impact and scratch resistance

-

Anti-slip coatings: Prevent cargo movement during transit

-

Color-coded finishes: Help organize different sections of your racking system

Installation Tips for Wooden Van Racking

Preparation

Proper preparation ensures optimal results:

-

Measure your van's interior dimensions precisely, accounting for wall curvature

-

Create detailed plans before cutting any materials

-

Pre-treat all wood with appropriate sealants

-

Ensure all edges will be accessible for finishing after installation

-

Account for van wall reinforcement points for secure mounting

Tools Required

Gather these essential tools before beginning:

-

Quality circular saw with fine-tooth blade

-

Electric drill with various bit sizes

-

Countersink bits for professional-looking screw installations

-

Carpenter's square and measuring tape

-

Sandpaper (various grits) and sanding block

-

Clamps for holding pieces during assembly

-

Appropriate screws and fixings (avoid cheap options)

Safety Considerations

Prioritize safety throughout the installation process:

-

Always wear appropriate PPE (eye protection, gloves, dust mask)

-

Ensure proper ventilation when applying finishes

-

Use appropriate lifting techniques for heavy panels

-

Secure all tools when working inside the van

-

Follow manufacturer guidelines for maximum load ratings

Step-by-Step Process

While specific installations vary, follow these general principles:

-

Install floor protection first as a foundation

-

Create a mounting framework attached to van body reinforcement points

-

Install vertical supports, ensuring they're perfectly plumb

-

Add horizontal shelving with appropriate support underneath

-

Incorporate dividers and specialized storage as needed

-

Apply edge protection to all exposed corners

-

Add securing mechanisms (bungee cords, straps, doors) to prevent cargo movement

Maintaining Your Wooden Van Racking

Regular Inspection

Establish a maintenance schedule:

-

Weekly visual inspection for damage

-

Monthly check of all mounting points and fixings

-

Quarterly thorough examination of structural integrity

-

Immediate attention to any signs of moisture damage

Cleaning Techniques

Proper cleaning preserves functionality:

-

Remove debris regularly from shelves and compartments

-

Wipe surfaces with a slightly damp cloth

-

Avoid excessive water that could penetrate wood

-

Use mild detergents for stubborn dirt

-

Apply furniture polish occasionally to maintain finish

Repair and Replacement Advice

Address issues promptly to prevent escalation:

-

Repair minor damage with appropriate wood fillers

-

Reapply protective finishes to scratched areas

-

Replace individual components rather than entire systems when possible

-

Consider upgrading high-wear areas with more durable materials during repairs

Frequently Asked Questions

What thickness of plywood is best for van racking?

For most applications, 12-15mm plywood provides the optimal balance between strength and weight. Increase to 18mm for heavy-load shelving or spans exceeding 600mm without support. Conversely, 9mm may suffice for vertical dividers or non-load-bearing components.

How do I protect my wooden van racking from moisture?

Apply multiple coats of marine-grade polyurethane varnish or specialist wood sealer to all surfaces, paying particular attention to end grain and cut edges. Consider using plastic or aluminum edge trim on exposed corners, and elevate the bottom of the racking slightly above the van floor to prevent water contact.

Can I build DIY van racking, or should I use a professional system?

DIY racking can be highly effective when properly designed and executed. Consider your specific requirements, budget, and skill level. Professional systems offer precision engineering and crash-tested safety but at a higher cost. Many tradespeople opt for a hybrid approach, combining commercial components with custom elements.

How much weight can wooden van shelving support?

Properly constructed 15mm birch plywood shelving can support 40-50kg per linear meter when correctly mounted. However, always consider the van's payload capacity and distribution rather than just shelf strength. Professional systems typically provide specific load ratings, whereas DIY installations should incorporate a significant safety margin.

How can I reduce noise from my wooden van racking?

Incorporate rubber or silicone buffers between components, use anti-vibration fixings like nyloc nuts, and ensure all joints are tight. Consider applying thin foam tape to surfaces where metal tools or equipment might contact the wood. Regular maintenance tightening of all fasteners also significantly reduces rattle development.

Conclusion

Selecting the right wood for your van racking represents a crucial investment in your mobile workplace efficiency. While budget considerations inevitably factor into decision-making, the long-term benefits of quality materials extend far beyond initial cost savings. A well-designed system built with appropriate woods enhances productivity, protects valuable equipment, improves fuel efficiency, and provides years of reliable service.

For most professional applications, marine-grade plywood or birch plywood delivers the optimal balance of performance characteristics. However, your specific industry requirements, vehicle type, and usage patterns should ultimately guide your selection. Consider consulting with specialist van outfitters who can provide tailored recommendations based on extensive experience across different sectors.

Remember that even the finest materials require proper installation and maintenance to perform at their best. Take time to plan thoroughly, execute carefully, and inspect regularly to maximize the return on your investment.