Ensuring your van is equipped with the right racking can transform a chaotic workspace into an organized haven for your tools and equipment. With a structured approach, you can build a system that caters to your needs, making your mobile workstation efficient and streamlined. This comprehensive guide delves into the aspects you're likely to encounter when crafting your racking system. We'll explore material options, safety regulations, and practical installation techniques, all while highlighting the industry's best practices.

Table of Contents:

-

Choosing the Right Material

-

Design Considerations

-

Safety Measures

-

Installation Techniques

-

Maintenance and Upkeep

Understanding Material Choices for Van Racking

When it comes to building racking in a van, the choice of material is critical. You're essentially deciding between steel and aluminum, two popular materials with distinct characteristics.

Steel vs. Aluminum Shelving

Steel shelving is renowned for its strength and durability. It's a top choice for heavy-duty storage, especially beneficial if you’re carrying substantial loads. However, steel is prone to corrosion, which requires regular maintenance to keep rust at bay. On the other hand, aluminum shelving is lightweight, reducing the overall weight burden on the van. While it's resistant to corrosion, it may not offer the same level of durability as steel, particularly in high-impact environments.

Attributes and Applications

Consider the environment in which your van operates. For frequent travel through high-humidity areas, aluminum might be more suitable due to its resistance to corrosion. Conversely, for a static, rugged use, steel might offer the robustness required for longevity. Understanding these attributes helps in tailoring your racking solution to maximize efficiency and lifespan.

Designing an Efficient Van Racking System

Crafting a design tailored to your van involves a meticulous understanding of space and functionality. The goal is to optimize your van's storage potential without compromising on safety or accessibility.

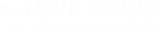

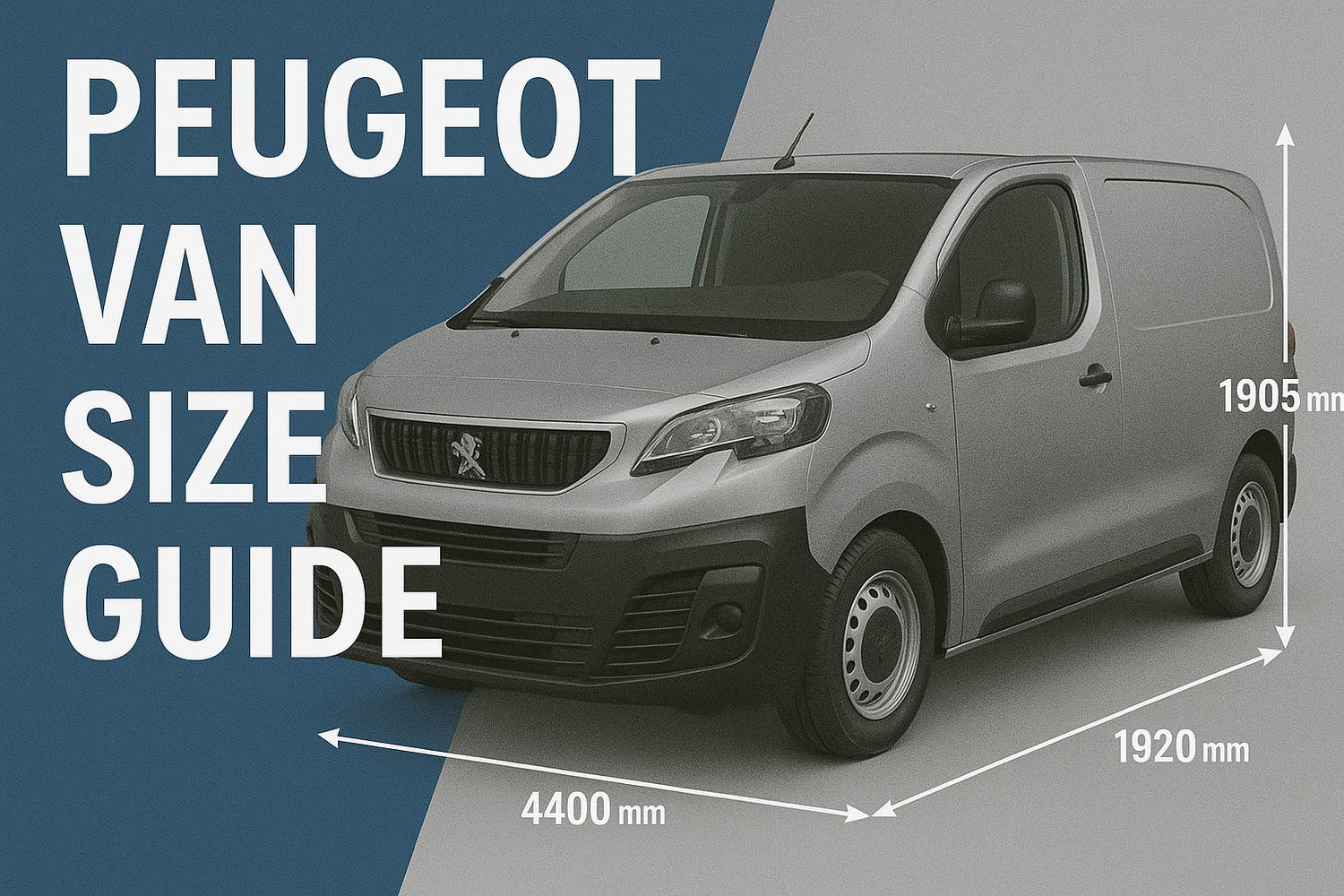

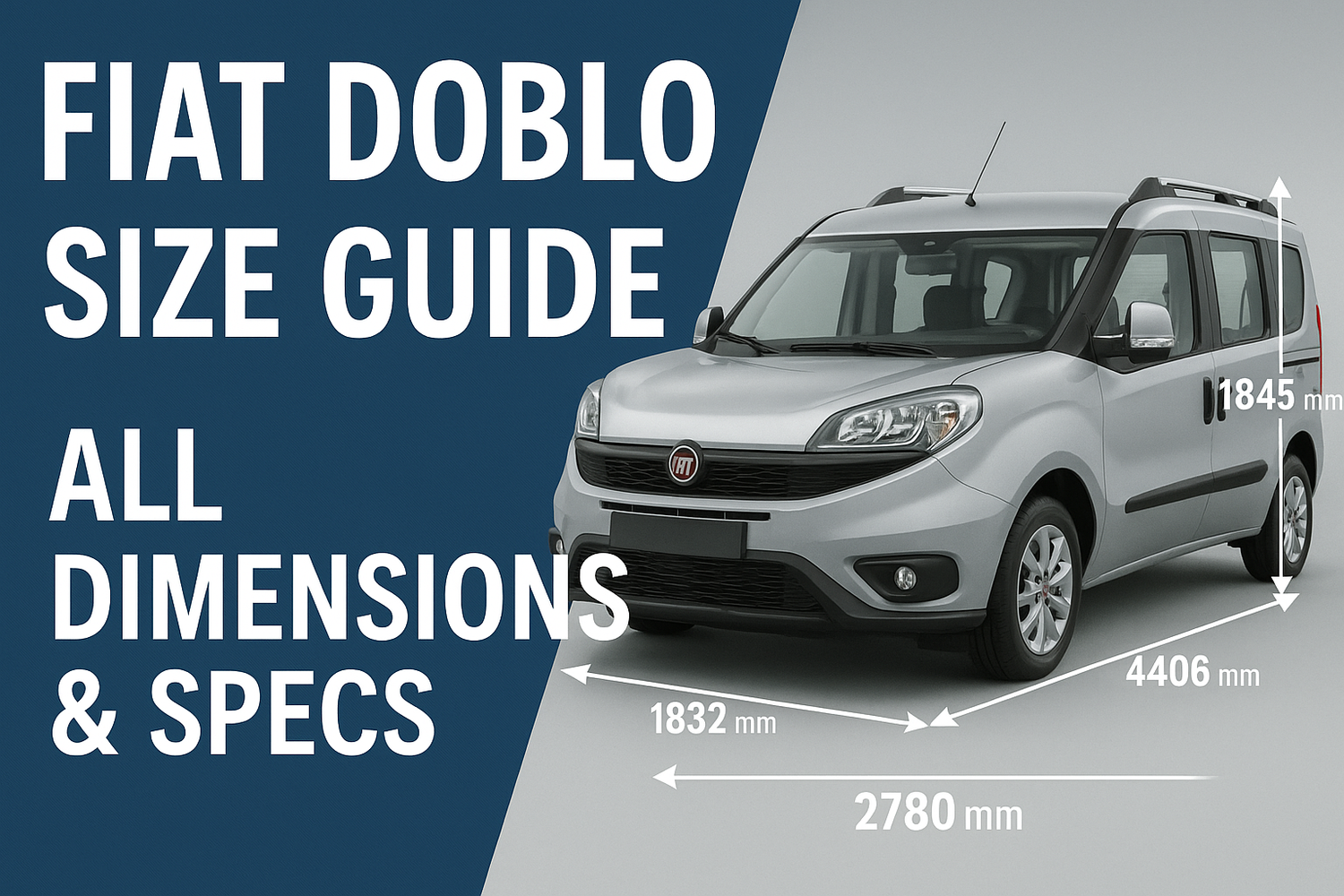

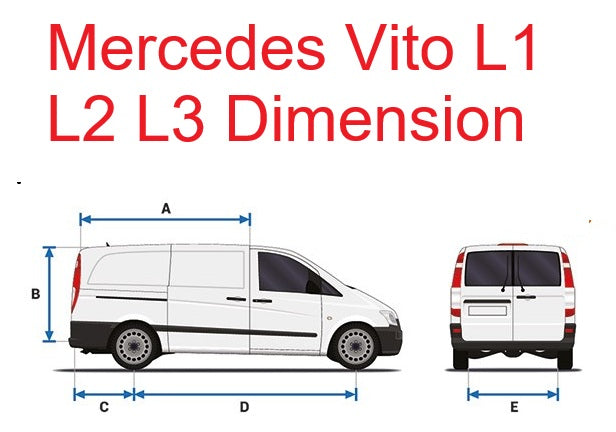

Measuring Your Van

Before you start designing, precise measurements of your van's interior are crucial. This ensures that every inch of space is utilized effectively, resulting in custom-fit shelving that meets your unique storage requirements. Take into account the width, height, and depth of the interior, remembering to leave space for maneuverability and access.

Planning the Racking System

A well-thought-out plan integrates seamlessly with the inner frame of the van, using every nook and cranny. Consider the weight distribution to avoid instability which can affect driving dynamics. Your racking plan should prioritize easy access to frequently used tools while securing heavier equipment to prevent shifting during transit.

Integrating with Van’s Structure

Secure attachments to the van’s floor and walls are paramount. Utilizing existing mounting points can enhance safety and avoid potential damage to the van's structural integrity. Let the core structure guide the installation process, ensuring it aligns with safety regulations and standards.

Prioritizing Safety in Van Racking

Safety is a non-negotiable aspect of building racking in a van. Proper securing mechanisms prevent serious accidents on the road.

Secure Racking Systems

Use high-grade brackets and fixings to ensure your racking remains stable. In a study, emphasis was placed on crash-tested racking, reinforcing the importance of systems that can withstand impact. Rigorous testing, like the compliance with ECR R17.07 standards, ensures occupants' safety under duress.

Preventing Accidents and Injuries

Incorporate tie-down points and bungee cords for additional security during transit. Evaluate the need for padding or barriers to cushion tools or equipment, reducing the risk of flying objects in a collision.

Safety Standards & Compliance

Adhering to industry standards such as ISO 27955 helps maintain compliance with legal requirements ensuring your van is roadworthy and safe. Regular checks and protocol updates align your systems with new regulations or advancements in safety technology.

Installation Techniques for Van Shelving

Implementing robust installation techniques is pivotal in constructing a reliable racking system.

Face Frame vs. European Box Systems

These two cabinet-making methods offer unique benefits. Face frame construction delivers a classic look with added stability, ideal for traditional formats. The European box system favors a minimalist design offering more space efficiency. Choose one that aligns with your design goals and overall functionality.

Practical Tips for Installation

According to THISisCarpentry, employing simple tools like a cordless drill, rivet gun, and a circular saw can simplify the installation process. Remember, pre-drilling holes and using high-grade adhesive can provide additional bonding to ensure longevity and robustness.

Maintaining Your Van Racking System

Maintenance can significantly extend the lifespan of your racking, assuring lasting performance.

Regular Checks and Upgrades

Consistent inspections, checking for signs of wear or corrosion, and addressing them promptly can keep your system in top condition. Consider seasonal maintenance campaigns, such as adding rust-proof coatings before winter.

Addressing Corrosion and Wear

For steel systems, combat rust by ensuring any scratches or bare metal is treated immediately with primer and paint. For aluminum, maintain cleanliness and check for structural integrity regularly to foresee any potential failures or weaknesses.

Future of Van Racking: Smart Technologies and Innovations

The industry is gradually embracing smart technology integrations. Systems that leverage IoT (Internet of Things) deliver real-time insight into load management and maintenance schedules, allowing for an informed, proactive approach to mobile storage solutions. While these technologies are still emerging, they promise to revolutionize the way you manage van racking.

Conclusion

Building racking in a van is not just about creating storage space; it’s about transforming how you operate on the move. By carefully considering materials, design, safety, and installation techniques, you can craft a solution that’s safe, efficient, and future-ready. The steps covered will help guide you toward building a system that perfectly aligns with your professional needs, ensuring you’re prepared for whatever the road can throw your way.

For further in-depth insights, consider visiting CNC Work to explore the latest trends in crash-tested van racking systems and their compliance with safety standards.

In adopting an approach focused on customization, safety, and technological integration, your van racking project won’t just meet current needs but will be poised to adapt to future demands. Happy outfitting!