In the world of van customizations, installing the right racking can significantly enhance utility, whether you're setting up a mobile workshop or organizing tools for easy access. But to achieve the perfect fit, precise measurements are pivotal. This guide will walk you through the steps involved in measuring a van for racking installation, ensuring a seamless setup.

Table of Contents

-

Understanding Van Dimensions

-

Preparing for the Measurement Process

-

Measurement Techniques

-

Choosing the Right Racking

-

Ensuring Compliance and Safety

-

Future Trends in Van Customization

Measuring a Van for Racking Installation: The Basics

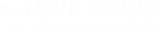

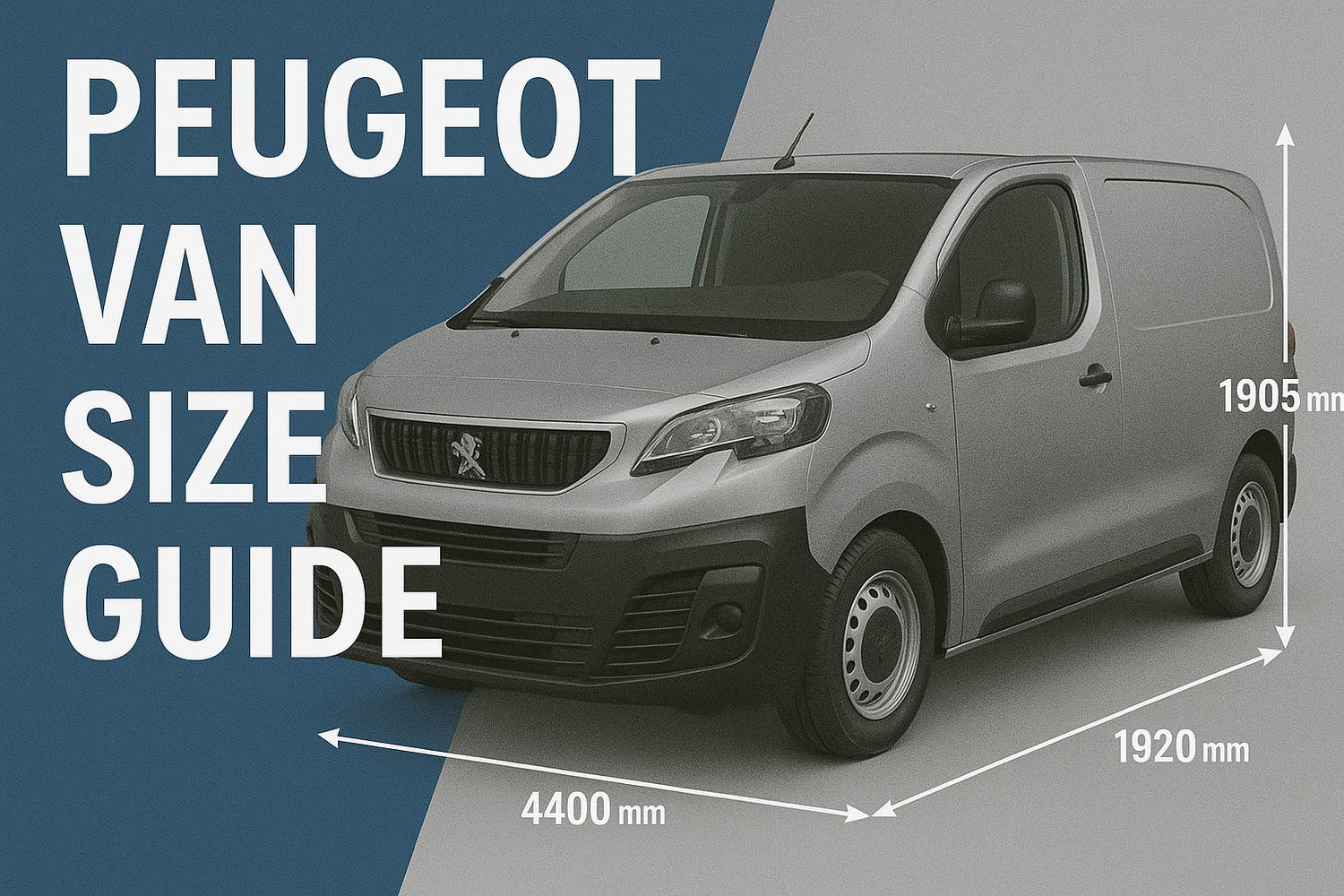

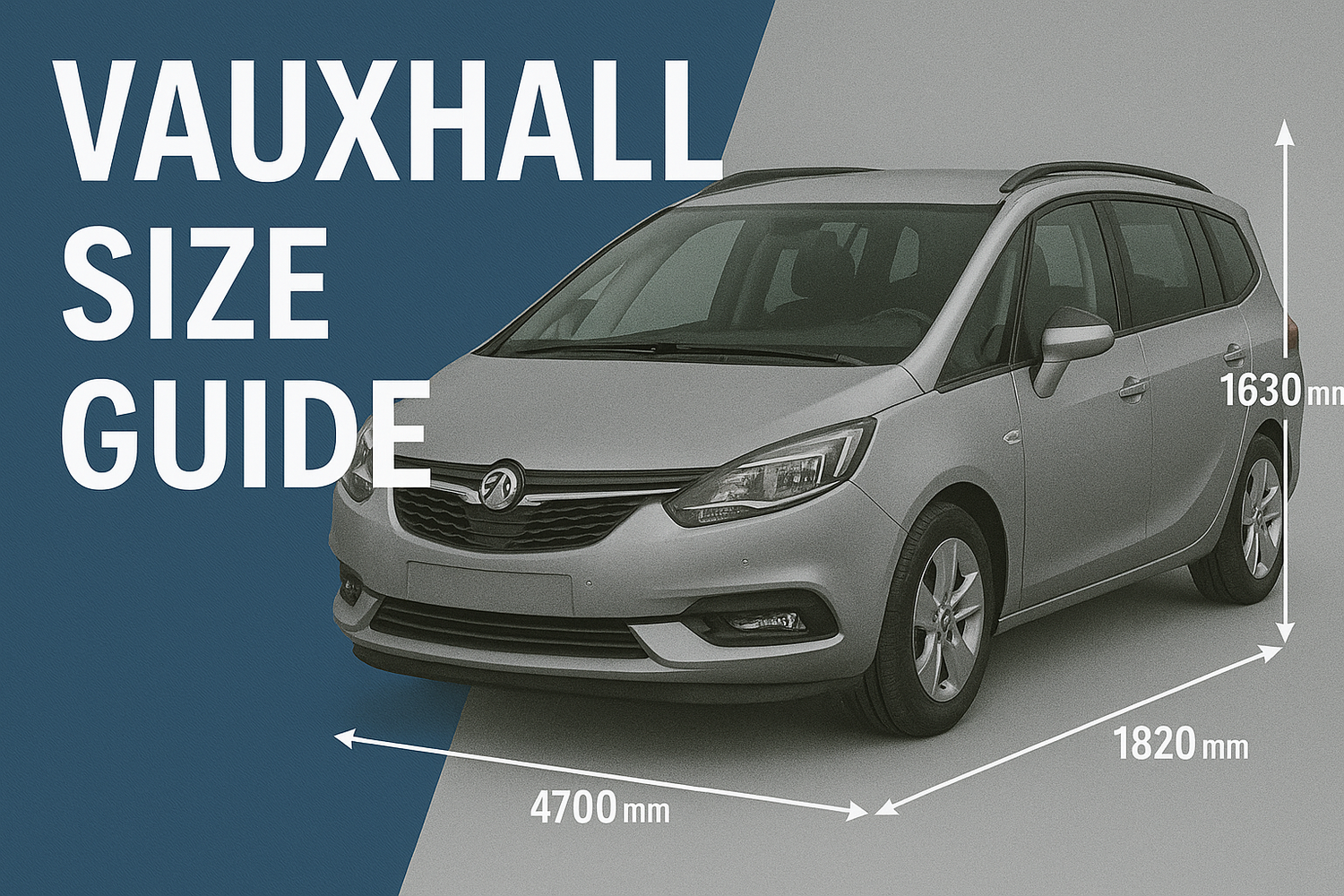

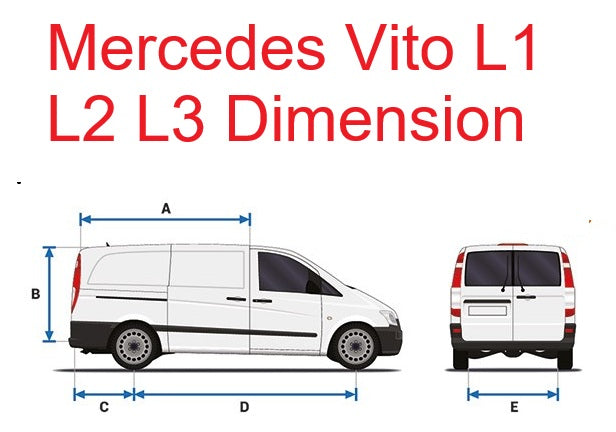

Understanding Van Dimensions

Understanding your van's dimensions is the fundamental step towards effective racking installation. Vans come in various shapes and sizes, commonly categorized through dimensions like L1, L2, L3, and H1, H2, H3. These refer to length and height, respectively, and help in determining the type of racking system that will best fit your vehicle.

According to the Loads of Vans blog, it's crucial to know that the wheelbase can significantly affect the choice of racking. This knowledge aids in ensuring that rack installation does not obstruct the doors or other vital van functions .

For instance, if you have a typical Transit Custom, knowing its dimensions will help configure the fitting process for a Sortimo SR5 efficiently. This includes using tools like CAD modeling software to ensure a precise fit .

Preparing for the Measurement Process

Essential Tools and Materials

Before diving into measurements, assembling the right tools is key. Essentials include a tape measure, marker, spirit level, and an adjustable wrench. It might be helpful to have someone assist you in holding the tape, especially when measuring longer sections.

Ensuring Precision

A common recommendation is ensuring the van is on a flat surface. Uneven ground can lead to inaccurate measurements, especially when marking the center between wheel arches or determining depth.

Measurement Techniques

Key Measurement Steps

-

Wheel Arch to Wheel Arch: Start by measuring from the center of one wheel arch to the other. Mark 485mm left and right from the center as suggested by BiGDUG .

-

Height and Depth Clearance: Ensure the rack does not impede door operations. Maintain a clearance height of at least 1100mm and depth of 280mm for average-sized racking systems .

-

Length of Safe Installation: This involves measuring from the rear entry to the back of the driver's seat, accounting for the thickness of the bulkhead.

The Yoke Vans installation guide provides additional tips on not only measuring but employing strategies like fixing racks securely and utilizing diagrams for visual aid .

Choosing the Right Racking

Customization and Flexibility

Customization can significantly impact the functionality and usability of van racks. Consider features such as adjustable shelves or compartments that align with your professional needs. BiGDUG, for instance, offers customizable solutions to cater to various demands .

Integration with Technology

One budding trend in van customization is integrating technology into racking solutions. Imagine racks with IoT-enabled systems for better inventory tracking, which enhance operational efficiency .

Advanced Tips and Industry Trends

Ensuring Compliance and Safety

Compliance with industry standards ensures safety and legality when modifying your vehicle. Many countries have specific regulations regarding weight distribution and securing loads in commercial vehicles. Consult local guidelines or experts in the field to avoid penalties and ensure safe vehicle operation.

Incorporating Sustainable Practices

The future of van racking lies in sustainability. Modern solutions are leaning towards using eco-friendly materials without compromising on strength and durability. This trend not only appeals to environmentally conscious consumers but also enhances the overall appeal of your business setup .

Practical Applications

From plumbers to electricians, properly installed van racking offers practical benefits by maximizing both space and time. Correct racking ensures essential tools and components are always within arm's reach, significantly enhancing job efficiency.

The Sortimo SR5 system exemplifies modern practicality through its precision fittings and robust setup techniques, showcasing the synergy between innovative design and field reliability .

The Future of Van Racking

Embracing Innovations

Predicting future trends, it's likely the integration of smart technologies and personalized rack adjustments could become the norm, catering even more closely to industry-specific needs. This could include automated inventory systems or even enhanced locking mechanisms for security .

Key Takeaways

Whether you are new to van racking or looking to upgrade your current setup, understanding how to measure for racking installation is pivotal. By combining careful preparation, precise measurements, and embracing technological advances, you can transform your van into the ultimate workhorse tailored to your needs.

Authoritative sources like BiGDUG and Sortimo offer insightful videos and guides to aid in this process, ensuring you not only achieve a high-functioning custom setup but also maintain compliance and safety in your professional ventures .

Maximize the potential of your van space with thoughtful considerations and strategies, and stay ahead in the dynamic field of van customizations by incorporating flexibility, compliance, and a touch of future-forward thinking.